Colloid microcrystalline cellulose anti caking agent uses guide: Have you ever scanned a food label and paused at a term like “microcrystalline cellulose“? These complex names can feel like a chemistry lecture, but the secret behind this one—and its role in preventing clumping—is surprisingly simple.

Often called cellulose gel, it is a pure form of plant fiber. It comes from the natural material found in plants. Refined into an incredibly fine powder, it forms an invisible network within food to hold everything perfectly in place.

That delicate network is the key to shredded cheese that doesn’t clump and creamy dressings that refuse to separate. Colloidal microcrystalline cellulose (MCC) is a powerful ingredient that improves texture.

Its popularity as an anti-caking agent fuels a large global market. In 2024, the market was worth an estimated $1.39 to $2.24 billion USD. Strong growth, mainly from food and drink products, should push its value to between $2.75 and $4.56 billion USD by 2034.

Cellulose is the tough, structural fiber that gives plants their shape. Plants use it to build the cell walls of everything from grass to trees. As the most common natural compound on Earth, we eat it every day. It creates the satisfying crunch in celery, the fibrous stems in broccoli, and the hearty texture of whole grains.

Our bodies don’t digest this insoluble fiber—it passes right through us, which is a normal and healthy process. For food ingredients, manufacturers source highly purified cellulose from sustainable plants.

Manufacturers make microcrystalline cellulose (MCC) from purified wood pulp or cotton. The final product is pure plant fiber, not wood. They take this clean plant source and run it through a multi-step refining process. This removes everything else—like lignin, oils, and minerals—and extracts only the pure, tasteless, odorless cellulose fiber.

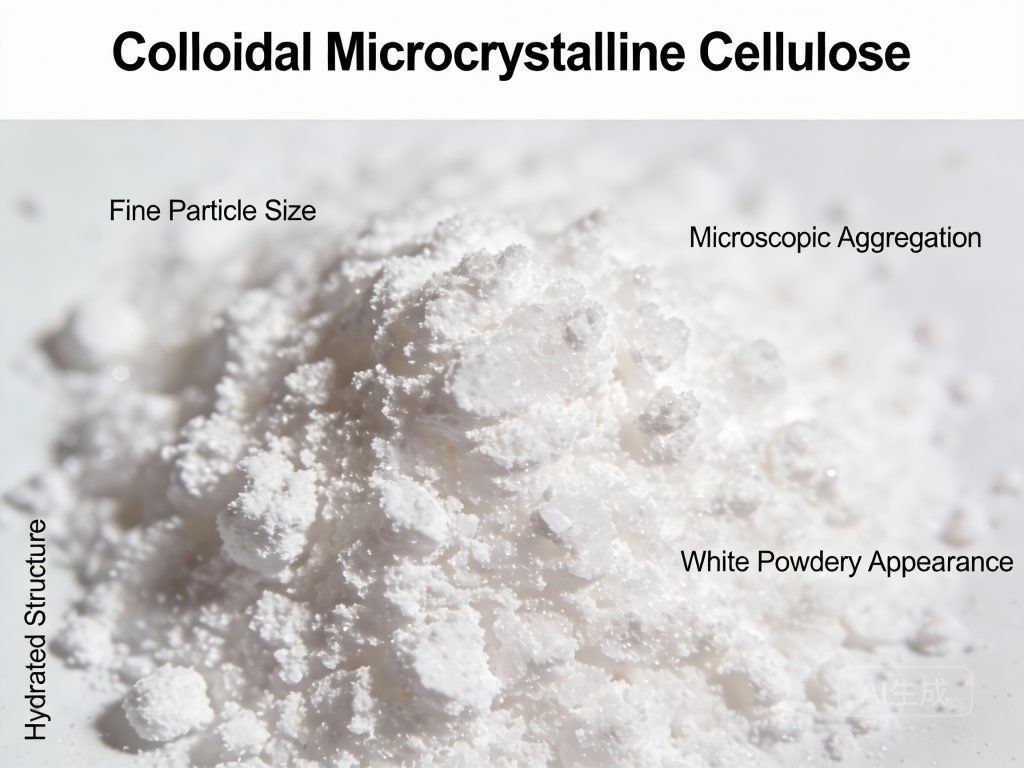

Next, they treat the long cellulose fibers with acid hydrolysis. This process breaks them down into incredibly tiny, microscopic particles with a structured, crystalline form. The name “microcrystalline cellulose” tells you exactly what it is: tiny, structured plant fibers.

This step turns rough fiber into a useful tool for creating texture in food. Food scientists control how well MCC flows as a powder by carefully adjusting its particle size and crystalline structure.

When you see “colloidal microcrystalline cellulose,” it usually doesn’t mean pure MCC. Instead, it refers to a special, synergistic blend. Formulators typically make this functional ingredient by mixing high-purity microcrystalline cellulose (MCC) with sodium carboxy methyl cellulose (CMC-Na).

The classic and highly effective mix uses about 13 parts MCC to 87 parts CMC-Na. In this team, the MCC provides the main particulate structure and gelling network. The CMC-Na acts as a protective colloid and dispersant, stabilizing the whole mixture in water. Working together, they create a much more functional ingredient than either one could alone.

The final product is a white powder. The manufacturer makes it only of pure, food-grade plant fiber.

That’s why regulators can clearly and confidently answer “yes” to the question, “Is microcrystalline cellulose safe to eat?”

When you mix MCC into a liquid, its particles don’t dissolve like sugar. The particles instead form cohesive bonds with one another.

They form an invisible, three-dimensional gel network—like a microscopic net woven through your salad dressing.

Scientists call this kind of mixture, where tiny particles suspend instead of dissolve, a colloid. This mechanism parallels the suspension of minute protein particles found in milk.

This invisible net shows us how suspension agents work to prevent separation. The net acts like a scaffold.

Beyond just holding particles, this net also masters texture in low-fat foods. It traps water molecules, creating a creamy, full-bodied mouthfeel that we normally link with fat. This is how a low-fat yogurt can feel rich and smooth without the extra calories from cream. Colloidal MCC cleverly uses the water already in a product to deliver a more satisfying texture.

Why the MCC/CMC-Na Blend Works So Well

The performance of this MCC/CMC-Na blend beats many single thickeners and stabilizers. By combining the unique benefits of both parts, it achieves stronger, more versatile functionality. MCC brings excellent heat stability, salt tolerance, and a clean mouthfeel that isn’t slimy.

CMC-Na provides powerful cold-water dissolving ability, a smooth texture, and better emulsion keeping stable. This strong combination helps colloidal MCC work well in complex foods. It easily manages tough conditions like changing pH, temperature, or salt levels.

Three Primary Applications of MCC as an Anti-Caking and Stabilizing Agent

Because this ingredient is so effective at managing texture and stability, colloidal microcrystalline cellulose serves distinct functions across various products.

In Shredded Cheese and Spices: The anti-caking agent in pre-shredded cheese is often microcrystalline cellulose (MCC).

Acting as an anti-caking agent, it forms a light barrier on each piece to prevent shreds from clumping into a solid block. In Shredded Cheese

Major food regulations explicitly permit its use here. It works by absorbing moisture and creating a physical barrier between cheese shreds to prevent clumping during storage. Manufacturers typically use it at levels of 2–3%.

Within ice cream formulations, the cellulose gel functions to immobilize water molecules.

This creates a creamy texture without adding fat, so it acts as a fat replacer. It also prevents large ice crystals from forming. This keeps the dessert smooth and not gritty. Besides specific uses, MCC is a versatile ingredient with many uses.

. It can work as a texturizer, fat substitute, mixer for oil and water, filler, and bulking agent.

In Vitamin Tablets

If you check the “inactive ingredients” on a supplement bottle, you will likely see MCC listed. It performs the essential role of a safe and effective binding agent.

Active ingredients like vitamins are in small amounts. This purified fiber adds bulk and keeps everything together in a solid tablet. Its high ordered structure also makes it an excellent free-flowing agent for supplement powders.

Applications and Market Context

Colloidal MCC has many more uses than these common examples. Strong regulations and significant market data support its widespread role.

Major global regulators widely recognize colloidal MCC (often labeled as MCC or “cellulose gel”) as safe. International food standards list it as an approved food additive. It functions as a thickener, stabilizer, and processing aid with set usage levels.

In North America, regulations permit its use as an anti-caking agent in shredded cheeses. Following a safety review, they have also approved it for plant-based cheese alternatives.

The European Union approves it as E460(i). You can use it as a thickener, stabilizer, or mixer for oil and water. This clear regulatory status supports its global use.

Market Size, Growth, and a Key Producer

The market value of MCC shows its commercial importance. In 2024, the global MCC market was worth an estimated $1.39–2.24 billion USD. Analysts project it will grow at a rate of about 7.06–7.34% per year, reaching $2.75–4.56 billion USD by 2034.

A key driver of this growth is rising demand in processed foods, where MCC serves as a fat substitute, bulking agent, and texturizer. The food and beverage segment is a major area of growth.

A concrete example of a global supplier is Qingdao Achieve Target Biological Technology Co., Ltd. Its colloidal MCC is a flagship product sold across China and exported to over 80 countries. To meet substantial global demand, the company maintains a production capacity of roughly 3,000 tons per year.

Beyond cheese, formulators use MCC in precise amounts across various foods:

The functional performance of MCC is not uniform and varies by product specification.

Its anti-caking power and properties like flow depend strongly on particle size and ordered structure. Food scientists can choose or adjust specific MCC grades to achieve the best results. They can aim for maximum flow, perfect suspension, or a certain mouthfeel.

Yes, microcrystalline cellulose is completely safe to eat. Agencies like the U.S. FDA classify it as “Generally Recognized as Safe” (GRAS). This places it in the same category as common ingredients like salt and vinegar. Approvals from regulators worldwide further confirm its safety.

Our bodies process it as insoluble fiber, just like the fiber in celery or corn. We don’t digest or absorb it; it simply passes through our system without adding calories. This makes it a harmless ingredient that improves texture without providing nutrition.

https://www.pcimag.com/articles/87416-colloidal-microcrystalline-cellulose