Microcrystalline cellulose is a purified, crystalline derivative of plant cellulose produced by acid hydrolysis that removes amorphous regions. Its hallmark properties—compressibility, flowability, inertness, and stability—enable broad use as a binder/filler and stabilizer in pharmaceuticals, foods, cosmetics, and industrial composites. This article contrasts natural cellulose, MCC, microfibrillated cellulose (MFC),and Cellulose colloidal microcrystalline 9004-34-6 explains structure–property relationships and production, and emphasizes MCC’s renewable, sustainable sourcing. It also highlights future directions including surface functionalization, MCC-based composites, and biomedical applications such as tissue engineering and drug delivery.

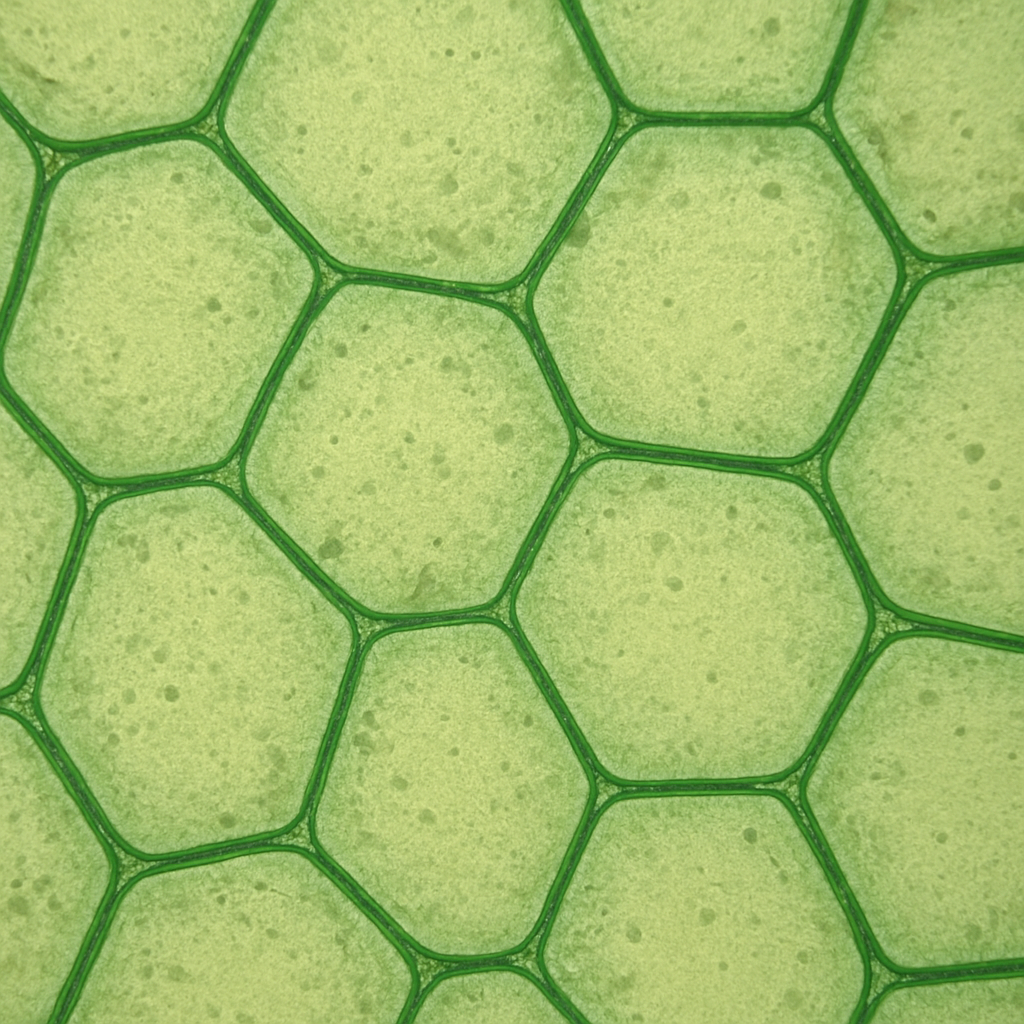

Cellulose is a complex carbohydrate or polysaccharide composed of glucose units. It’s the most abundant organic polymer on Earth, providing structural support to plant cell walls. The degree of polymerization, which refers to the number of glucose units in a cellulose molecule, varies depending on the source and processing method.

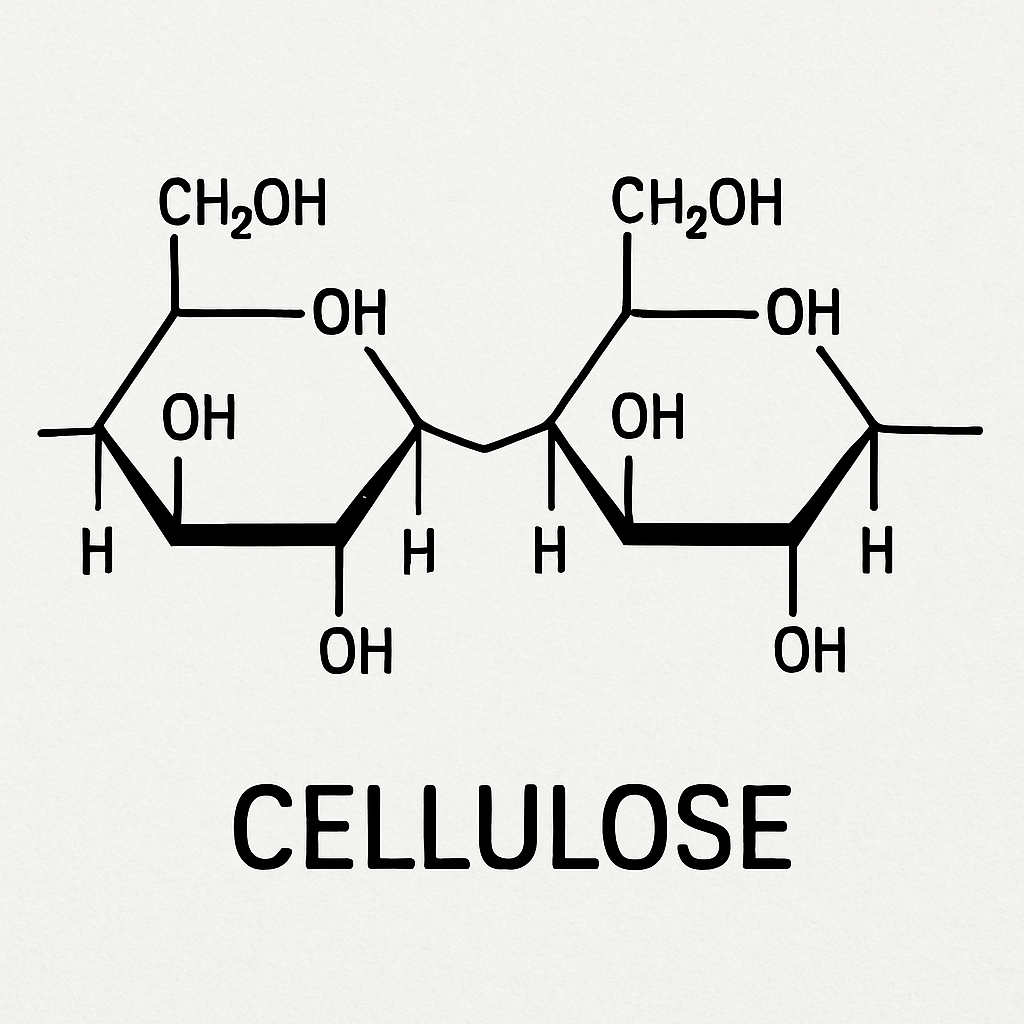

Cellulose molecules are linear chains of glucose units linked by β(1→4) glycosidic bonds. This configuration results in a rigid structure that contributes to its high tensile strength. The arrangement of these molecules in plant cell walls forms a microfibril network that is crucial for maintaining plant rigidity and resistance to external forces. Understanding this structure helps in tailoring cellulose for specific industrial applications.

Natural cellulose is found in its raw form in plant cell walls. It’s a fibrous and water-insoluble material. On the other hand, microcrystalline cellulose (MCC) is a refined form of cellulose, commonly used as a food additive, pharmaceutical excipient, and in various industrial applications. Its unique properties make it a versatile material in several sectors.

Natural cellulose is known for its fibrous nature and insolubility in water, which makes it ideal for providing structural support in plants. In its natural form, cellulose is often combined with other polysaccharides and lignin to form the complex matrix of plant tissues. This complexity can be both a challenge and an advantage, as it requires careful processing to isolate cellulose for industrial uses, yet provides diverse functional properties.

The conversion of natural cellulose into microcrystalline cellulose involves breaking down the fibrous structure to enhance its usability. This process typically involves acid hydrolysis to remove amorphous cellulose regions, resulting in a material that is more crystalline and has distinct functional properties. The transformation enhances its mechanical characteristics, making it suitable for various applications such as pharmaceuticals and food products.

In the vast world of natural polymers, cellulose stands out as an essential component found in plant cell walls. Its unique structure and properties make it a key material in various applications. This article delves into the details of cellulose colloidal microcrystalline, focusing on its benefits, applications, and the science behind it.

Cellulose colloidal microcrystalline 9004-34-6 is a purified, crystalline derivative of plant cellulose produced by acid hydrolysis, which removes amorphous regions. Its key properties—compressibility, flowability, inertness, and stability—make it widely used as a binder/filler and stabilizer in pharmaceuticals, food products, cosmetics, and industrial composites. This article compares natural cellulose, MCC, and microfibrillated cellulose (MFC), explains the structure-property relationships and production methods, and highlights the renewable, sustainable sourcing of MCC. It also discusses future research directions, including surface functionalization, MCC-based composites, and biomedical applications such as tissue engineering and drug delivery.

Cellulose colloidal microcrystalline 9004-34-6 are commonly used as excipients in the pharmaceutical industry for tablet binding and stabilization. These materials improve the flowability and compressibility of powdered formulations, making them ideal for tablet manufacturing. Their ability to hold ingredients together in a stable matrix ensures consistent dosing and enhances the stability of the final product.

Cellulose colloidal microcrystalline 9004-34-6 is a widely utilized filler in the formulation of dietary supplements and nutraceuticals. MCC is an inert, non-reactive material that can be safely incorporated into capsules and tablets, helping to increase the volume of the product without compromising its stability or efficacy.

Cellulose colloidal is known for its high water retention capacity, making it useful in both food and cosmetic formulations. This property allows it to act as a humectant, which helps products retain moisture, improving texture and stability. In cosmetics, it contributes to the smooth application and feel of lotions and creams.

Microcrystalline cellulose (MCC) is highly valued for its ability to improve the texture and mouthfeel of food products. It enhances the body and consistency of food items like sauces, dressings, and baked goods. Its ability to provide a desirable texture without adding calories makes it an ideal choice for low-calorie or dietary food formulations.

Both cellulose colloidal and MCC are considered safe and non-toxic for human consumption by regulatory agencies like the FDA. These materials have been extensively tested for safety and are approved for use in food, pharmaceuticals, and cosmetics. Their inert properties ensure that they do not interact with other ingredients or cause adverse effects.

The production of Cellulose colloidal microcrystalline 9004-34-6 involves acid hydrolysis of cellulose, which reduces the molecular size of the fiber. This controlled process removes amorphous cellulose regions, leaving behind crystalline structures that contribute to its unique mechanical properties. The resulting material is refined to ensure purity and consistency, making it suitable for various applications.

The use of microcrystalline cellulose in pharmaceuticals improves the flowability and compressibility of powdered formulations. This makes MCC an essential ingredient in tablet production, ensuring that ingredients mix evenly and the tablets maintain their strength and stability. MCC also prevents caking and clumping, contributing to smooth production processes.

Both cellulose colloidal and MCC are biodegradable, making them environmentally friendly alternatives to synthetic additives. Their natural origin from renewable plant resources ensures that they contribute to a more sustainable and eco-conscious approach in the manufacturing of food, pharmaceuticals, and cosmetics.

Microcrystalline cellulose has the potential to act as a sustainable replacement for plastic-based additives in food packaging. Its biodegradable nature makes it an excellent candidate for use in eco-friendly packaging solutions. By replacing plastic additives with MCC, industries can reduce their reliance on non-renewable resources and promote environmental sustainability.

Cellulose colloidal’s ability to form gels and thicken liquids makes it an essential ingredient in many cosmetic and personal care products. It contributes to the texture, stability, and sensory properties of products like shampoos, lotions, and creams. Its versatility and non-toxicity make it a preferred ingredient for various cosmetic formulations.

Cellulose molecules are linear chains of glucose units linked by β(1→4) glycosidic bonds. This configuration creates a rigid structure that contributes to cellulose’s high tensile strength. These molecules form a microfibrillar network in plant cell walls, essential for maintaining plant rigidity and resistance to external forces. Understanding this structure helps in tailoring cellulose for specific industrial applications.

Natural cellulose exists in its raw fibrous form in plant cell walls, and is insoluble in water. In contrast, microcrystalline cellulose (MCC) is a refined form of cellulose, widely used as a food additive, pharmaceutical excipient, and in various industrial applications. Its unique properties make it a versatile material for many sectors.

Natural cellulose is known for its fibrous nature and insolubility in water, which makes it ideal for providing structural support in plants. In its natural state, cellulose is often mixed with other polysaccharides and lignin to form the complex matrix of plant tissues. This complexity can be both a challenge and an advantage because it requires careful processing to isolate usable cellulose for industrial purposes while providing diverse functional properties.

The transformation of natural cellulose into microcrystalline cellulose involves breaking down the fibrous structure to enhance its usability. Typically, this process involves acid hydrolysis to remove the amorphous regions of cellulose, resulting in a more crystalline material with distinct functional properties. This transformation improves its mechanical characteristics, making it suitable for a variety of applications in pharmaceuticals and food products.

Microcrystalline cellulose is used across various industries due to its versatility. In the pharmaceutical industry, it functions as a binder and filler in tablet formulations, while in food, it acts as a stabilizer and anti-caking agent. Its inertness also makes it valuable in cosmetics, where it enhances texture without reacting with other ingredients. The benefits of MCC are largely due to its ability to improve product stability, consistency, and mechanical properties.

Microcrystalline cellulose (MCC) 9004-34-6 is a remarkable material with diverse applications and significant benefits. Its role in promoting sustainability, along with its versatile properties, makes it an essential component in various industries. As research continues to uncover new applications and enhance its properties, MCC’s importance in material science and industrial sectors is set to grow.

Incorporating MCC into your products not only enhances their performance but also aligns with the global shift toward sustainable, eco-friendly solutions. Adopting such materials is a step toward a more sustainable future, where innovation meets responsibility. By choosing MCC, industries can contribute to a healthier planet while meeting the evolving demands of consumers and regulators.

Question: What does “Cellulose colloidal microcrystalline 9004-34-6” refer to?

Short answer: It refers to microcrystalline cellulose (MCC), a refined, crystalline form of natural cellulose identified by the CAS number 9004-34-6. Produced via acid hydrolysis of plant-derived cellulose, MCC is an inert, fine white powder valued for its compressibility, flowability, and stabilizing behavior in formulations across pharmaceuticals, foods, cosmetics, and industrial composites.

Question: How is microcrystalline cellulose (MCC) different from natural cellulose and microfibrillated cellulose (MFC)?

Short answer: Natural cellulose is the fibrous, water-insoluble structural polymer found in plant cell walls, often intertwined with other polysaccharides and lignin. MCC is a purified, crystalline fraction obtained by removing amorphous regions via acid hydrolysis, yielding a powder with excellent compressibility and flow—ideal as a binder/filler and stabilizer. MFC is produced by mechanically fibrillating cellulose into micro-sized fibrils, offering high strength and lightweight reinforcement for uses like packaging, coatings, and composites.

Question: How is MCC produced, and why does removing amorphous regions matter?

Short answer: MCC is made through controlled mineral acid hydrolysis (commonly hydrochloric acid) that selectively removes amorphous cellulose. The remaining crystalline material is neutralized, washed, and dried. This increase in crystallinity underpins MCC’s hallmark properties—superior compressibility, good flow, mechanical stability, and inertness—making it reliable in tablets, food systems, and other precision applications.

https://www.pharmaexcipients.com/microcrystalline-cellulose-mcc-pharma/

https://pmc.ncbi.nlm.nih.gov/articles/PMC4647644/

“Role of Microcrystalline Cellulose in Pharmaceutical Industry”

https://www.celluloseankit.com/role-of-microcrystalline-cellulose-in-pharmaceutical-industry/

“An update on microcrystalline cellulose in direct compression”

https://www.sciencedirect.com/science/article/abs/pii/S0144861721013552

“The Role of Microcrystalline Cellulose as a Binder and Disintegrant …”

https://www.nbinno.com/article/pharmaceutical-intermediates/role-of-microcrystalline-cellulose-binder-disintegrant