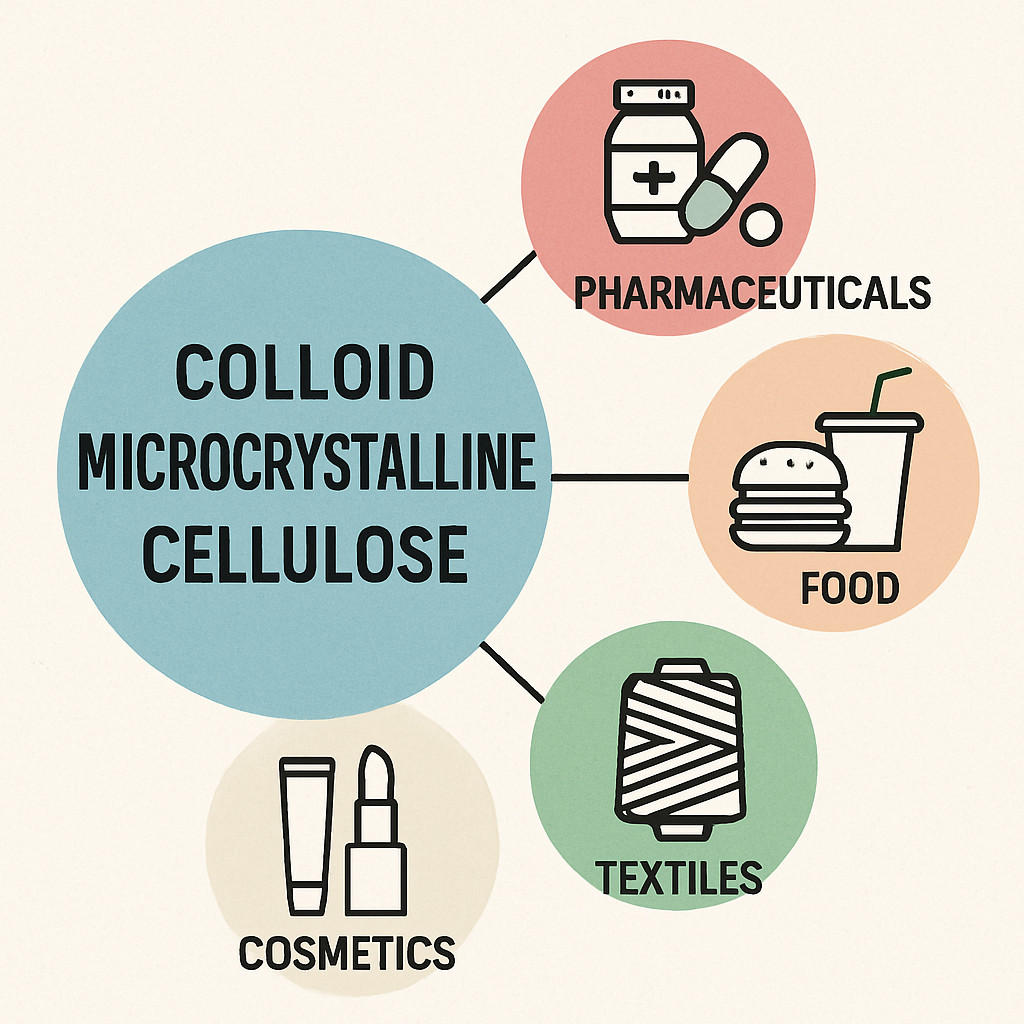

In today’s food, drug, and special products, performance is not just about one function like thickening or binding. Instead, formulators increasingly demand versatile ingredient systems capable of delivering structure, stability, and processing robustness simultaneously.In this context, colloidal microcrystalline cellulose (Colloid microcrystalline cellulose: premium & high-performance) has become a top choice. Many industries widely use it in food, pharm, cosmetics, and special industrial applications.

Microcrystalline cellulose (MCC) is a purified, partially broken down cellulose derived from plant pulp. It consists of highly crystalline cellulose domains with excellent mechanical strength, chemical inertness, and acid resistance. Typical pharmand food-grade MCC has high structure. It has low ability to dissolve and strong resistance to hydrolysis in many pH levels.

Colloidal microcrystalline cellulose, often referred to as cellulose gel, is not simply MCC dispersed in water. A co-processed, engineered system composed of:

Through controlled co-processing and particle engineering, these components form a three-dimensional colloidal gel network upon hydration. At solid levels as low as 1–3%, the system mixes evenly in water. It stays stable over time without quickly settling or separating.

This co-processed design sets colloidal MCC apart from single-component MCC or CMC-Na used alone. It allows for functions that neither component can provide on its own.

When mixed with water at low concentrations (usually 1–3% by weight), colloidal MCC forms a soft but effective gel. It has:

Viscosity measurements usually range from 50 to 200 mPa·s at these low concentrations. The gel structure recovers quickly when stirring stops. This rheological profile allows for:

Such behavior proves particularly valuable in suspensions, dressings, sauces, liquid pharm, cosmetic emulsions, and beverage systems, where both many uses and shelf stability are necessary.

Unlike standard MCC or CMC-Na, colloidal MCC delivers multiple functional roles within a single ingredient system, including:

This many uses significantly extends the application range beyond what MCC or CMC-Na can achieve separately. In complex food and pharm products, colloidal MCC can replace two or more thickening agents. This makes formulations simpler and keeps products stable and consistent from batch to batch.

A key performance advantage of colloidal MCC lies in the synergistic interaction between:

In acidic environments (typically pH 3.0–4.5), where many hydrocolloids experience viscosity loss or structural collapse, colloidal MCC demonstrates superior viscosity retention and structural integrity. The insoluble MCC particles act as a rigid scaffold, while the hydrated CMC-Na maintains network cohesion. As a result, colloidal MCC maintains rheological stability throughout the shelf life, performing better than CMC-Na used alone.

In food formulations, colloidal MCC functions as a structuring and keep stable system rather than a simple thickener.

Measured and observed performance benefits include:

Typical application areas include:

Typical use levels are 0.1–0.6% for beverages and dairy products, and 1.0–3.0% for sauces, dressings, and structured foods, depending on the desired texture and stability.

Typical use levels are 0.1–0.6% for beverages and dairy products, and 1.0–3.0% for sauces, dressings, and structured foods, depending on the desired texture and stability.

In pharm, colloidal MCC helps keep particles mixed and liquids or gels stable.

Key functional benefits include:

At typical use levels of ~0.5–2.5%, colloidal MCC forms a thixotropic network that allows easy redispersion while maintaining suspension stability at rest. In solid medicines, MCC helps tablets hold together and stay strong

In creams, lotions, and gel-based formulations, colloidal MCC contributes:

It is plant-based, safe, and gentle, making it suitable for sensitive skin and natural cosmetics

Colloidal MCC exhibits high stability across common food and pharm processing conditions, including:

It keeps its shape when heated and holds water well, so it doesn’t separate or get damaged when frozen and thawed

Microcrystalline cellulose and its colloidal forms are:

Regulatory authorities like JECFA and EFSA say microcrystalline cellulose is very safe, with no daily limit needed.

Made from plants, colloidal MCC can break down naturally and is safe for the environment, making it a greener choice than some synthetic thickeners and stabilizers.

From both formulation and processing perspectives, colloidal MCC delivers a unique combination of advantages:

These features explain why top suppliers like Roquette, JRS, and FMC (IFF) choose colloidal MCC for structure and stability.

Conclusion

Colloid microcrystalline cellulose: premium & high-performance

Colloidal MCC is a special type of MCC that makes products better.

It mixes MCC’s strong structure with CMC-Na’s water-holding and gel power to keep food, medicine, cosmetics, and other products stable and easy to use.

For manufacturers seeking premium product quality, formulation robustness, and long-term stability, colloidal MCC offers a proven, future-ready solution.

https://apps.who.int/food-additives-contaminants-jecfa-database/chemical.aspx?chemID=281