Colloid microcrystalline cellulose (MCC) is a versatile compound widely used across pharm, food production, cosmetics, and industrial applications. Its unique properties—binding, thickening, stabilizing, and suspending—make it an essential ingredient in various industries. This article explores its primary applications, manufacturing processes, and industrial uses.

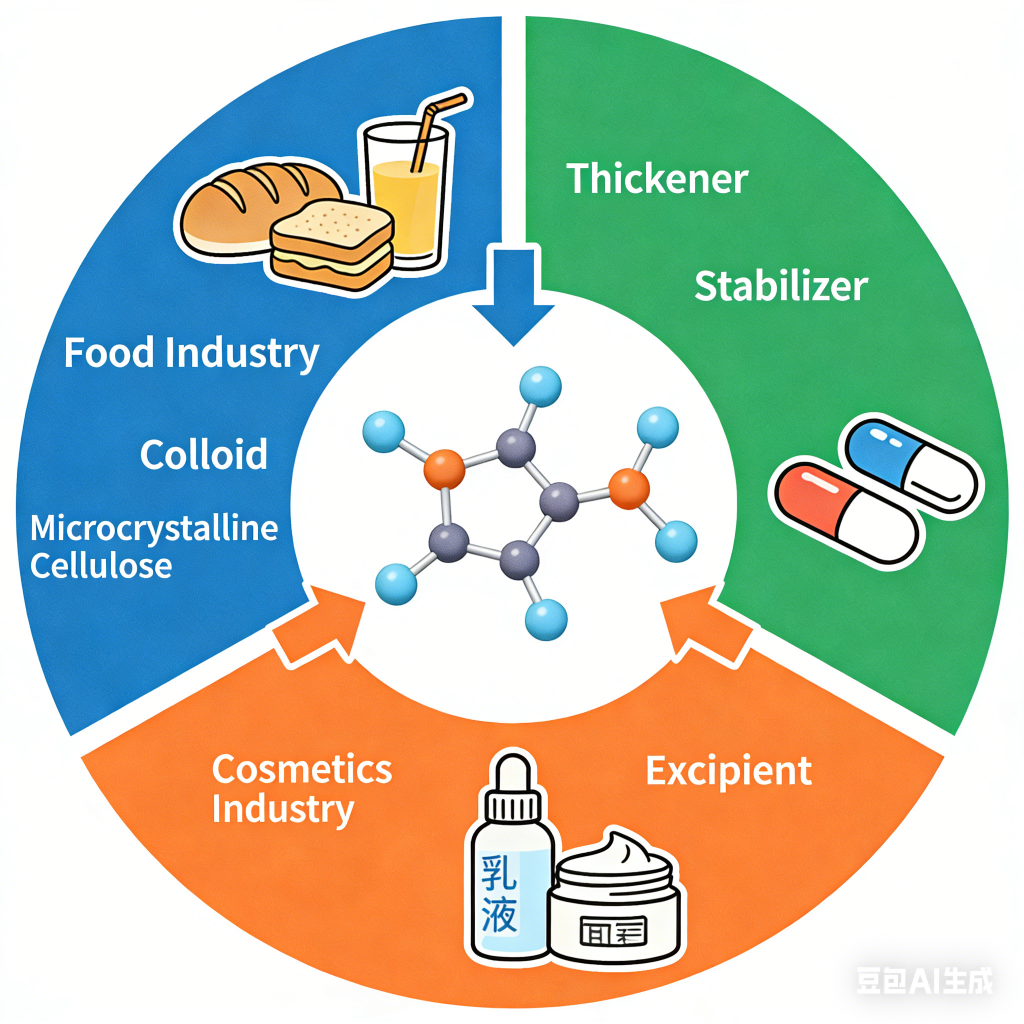

Colloid microcrystalline cellulose (MCC) is a plant-derived, acid-hydrolyzed cellulose with crystalline, colloidal characteristics. It functions as a binder, thickener, stabilizer, and suspending agent. MCC is widely used in:

Colloid Microcrystalline Cellulose Primary Applications works as a suspending agent and a rheology modifier. It can also work well with other cellulose derivatives. This helps improve mixing and body absorption.

Its safe and inactive nature allows users to utilize it in both dry and liquid forms. This supports the growing demand and new uses.

Explore the primary applications of Colloid Microcrystalline Cellulose as a critical thickener and stabilizer in pharmaceuticals, foodstuffs, and cosmetics

MCC is derived from plant cellulose, primarily wood pulp and cotton, via acid hydrolysis. This process removes amorphous regions of cellulose, leaving highly ordered crystalline domains that confer:

MCC is a fine white powder. It does not dissolve in water, but it can swell and mix into stable colloidal suspensions. These properties make it effective as a thickener, stabilizer, and suspending agent in both dry and aqueous formulations.

MCC acts as a binder and diluent in tablets and capsules. It helps create strong tablets and ensures even distribution of APIs. It allows for precise dosing, even in low-dose forms. This makes it one of the most common excipients in solid oral drugs.

MCC enables direct compression tableting, simplifying manufacturing, reducing production costs, and minimizing exposure to heat or moisture—ideal for heat- or moisture-sensitive APIs.

Different MCC grades vary in particle size and moisture content. This helps formulators improve flow, give, and tablet hardness for specific needs.

MCC promotes tablet cohesion and, simultaneously, rapid dissolving through capillary action and internal swelling, enhancing API release and absorption.

MCC is chemically inert and generally recognized as safe (GRAS), compatible with diverse APIs including sensitive compounds.

Makers use strong acid to break down alpha-cellulose from refined wood pulp to create MCC. This process creates a high-purity, consistent, and stable excipient. The industry is exploring sustainable cellulose sources, including agricultural residues, to reduce reliance on wood.

MCC is often mixed with other ingredients, like silicon dioxide. This helps improve flow and evenness in high-drug-load formulas. Over-lubrication with hydrophobic compounds can reduce binding efficiency, so careful formulation is essential.

Researchers often use MCC in placebos because it is inactive and resembles active drugs. This keeps the blinding in clinical trials.

Manufacturers mainly use colloidal MCC (CMC) as a stabilizer, thickener, and suspending agent. You can find it in food, pharm, cosmetics, and industrial coatings. CMC creates a 3D network that stops phase separation and particle settling.

Colloid microcrystalline cellulose is a versatile and essential ingredient across pharm, food systems, cosmetics, and industrial formulations. Its binding, thickening, stabilizing, and suspending capabilities—combined with regulatory safety and formulation flexibility—ensure its continued importance in modern manufacturing. As innovation and long-term workability become more important, experts expect MCC’s uses to grow. This will strengthen its role as a key excipient in many industries.