Microcrystalline Cellulose: What Is It and Where Is It Used? Microcrystalline Cellulose (MCC) is a term commonly encountered in the pharmaceutical and food industries. Manufacturers derive this white powder from refined wood pulp. It is highly valued for its excellent ability to form solid tablets and for its diverse applications. Consequently, MCC plays a significant role in a wide range of industrial sectors.

Scientifically, microcrystalline cellulose is derived from cellulose, a natural polymer found in plant cell walls. It is produced by treating plant pulp with controlled acid hydrolysis. This process removes the amorphous regions of cellulose, leaving behind smaller crystalline particles. The final product is a fine, white, odorless, tasteless powder that is inert, stable, and highly functional.

The pharmaceutical industry is one of the largest consumers of MCC. Manufacturers frequently use MCC in tablets and capsules. It acts as a binder and filler, helping to keep tablets strong and stable during manufacturing, transportation, and storage.

MCC aids in the proper disintegration of tablets after swallowing, ensuring the correct release of the active drug. In liquid and semi-solid formulations, MCC helps to keep ingredients evenly suspended and mixed. Its insolubility and non-reactivity with other substances make it particularly useful in advanced drug delivery systems. Formulators utilize MCC in controlled- or modified-release tablets by combining it with other functional materials.

Similarly, microcrystalline cellulose plays a crucial role in food production.

Within the food industry, MCC is widely employed as a stabilizer, anti-caking agent, texture modifier, and bulking agent. It prevents clumping in powdered foods and improves consistency in processed products. Furthermore, MCC enhances the texture, mouthfeel, and creaminess of products such as sauces, dairy items, salad dressings, and ice creams. Its ability to stabilize emulsions and suspensions helps maintain product quality and consistency, while also contributing to shelf stability, making it a reliable ingredient in many everyday food items.

Manufacturers use MCC in cosmetics to thicken and stabilize products. It improves the texture of creams, lotions, sunscreens, and powders. MCC helps maintain a smooth and consistent texture in products, ensuring they remain stable throughout their shelf life and improving their application properties.

Moreover, microcrystalline cellulose finds numerous applications in industrial sectors.

In industrial applications, MCC serves as a binder and stabilizer in ceramics, composites, and paints. It helps hold particles together and enhances product stability. Its plant-based origin, low toxicity, and reliability make it suitable for various non-consumer uses.

Structure and Nutritional Profile

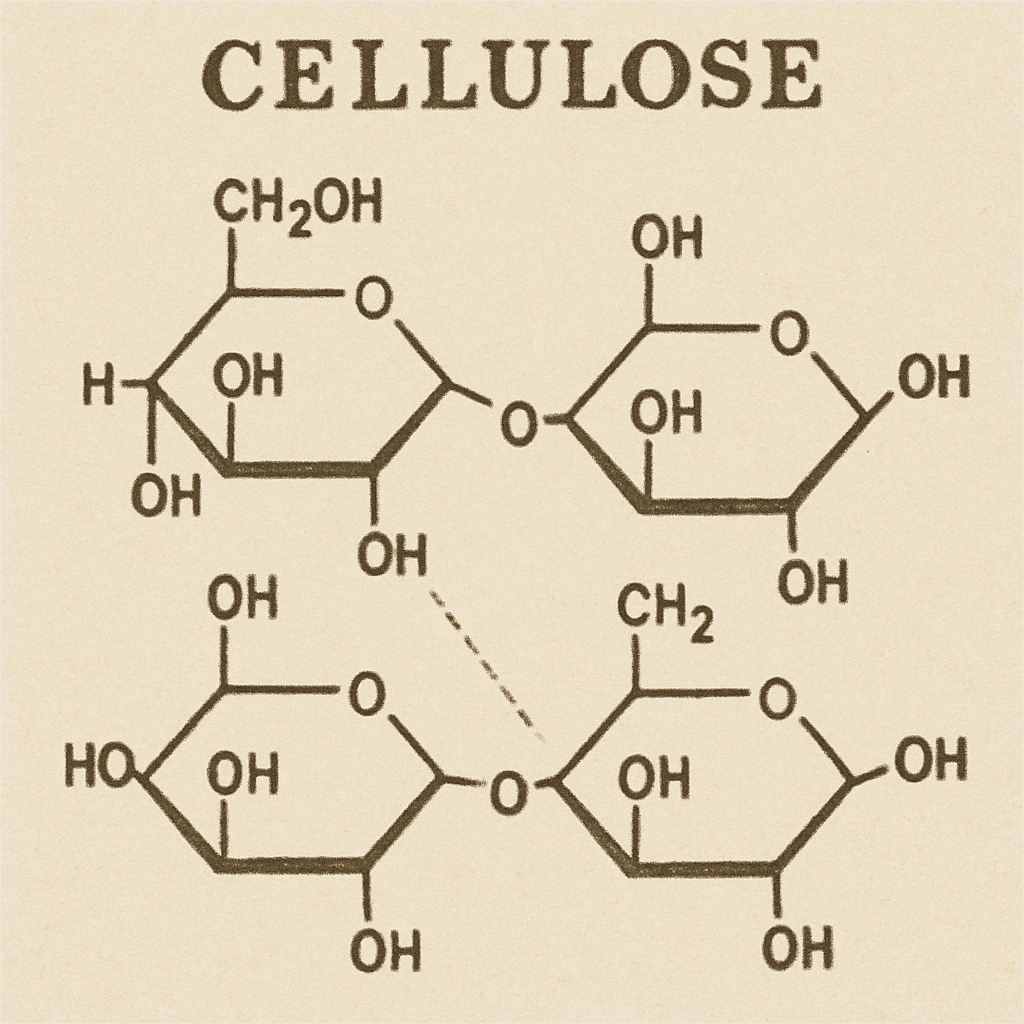

Microcrystalline cellulose consists of linear chains of glucose units linked by β-1,4-glycosidic bonds. It is manufactured by breaking down natural cellulose into fine, short, rod-like, or porous particles. The result is a white, odorless, tasteless crystalline powder.

Approximately 70% of the cellulose in plants is crystalline, while 30% is amorphous. This crystalline structure is responsible for MCC’s strength, stability, and functionality. MCC is also a non-digestible dietary fiber that can add bulk and support digestion when incorporated into foods.

MCC is produced worldwide, with manufacturers located in Europe, Japan, and China. Prices typically range from 15,000 to 22,000 RMB per ton, depending on particle size and grade. Most Chinese producers now utilize spray-drying technology, which improves particle consistency, flowability, and overall quality.

Regulatory authorities globally consider MCC safe for use in food, pharmaceutical, and cosmetic products. Organizations such as the U.S. Food and Drug Administration (FDA) and the Joint FAO/WHO Expert Committee on Food Additives (JECFA) classify MCC as a safe and inert substance, permitting its widespread use in regulated products.

In summary, microcrystalline cellulose is a reliable, versatile, and beneficial component found in pharmaceutical, food, cosmetic, and industrial goods. Its abilities to bind, bulk, stabilize, and texture render it an essential material. As production methods advance and the demand for plant-based materials increases, the utilization of MCC by manufacturers continues to grow, and its importance is set to rise further.

https://www.sciencedirect.com/topics/neuroscience/microcrystalline-cellulose