Microcrystalline cellulose in pharm industry is a highly valued component. It is renowned for its exceptional qualities that enhance drug formulation. This key ingredient is made from wood pulp, and a process called reactive extrusion shortens its cellulose chains. This makes the product purer and more versatile for various applications.

MCC is a white, free-flowing powder known for its excellent compressibility and anti caking properties. MCC is a common ingredient in tablets because it makes them stronger and better quality.

According to the Select Committee on GRAS Substances, microcrystalline cellulose is generally regarded as safe when used in normal quantities.

https://www.drugs.com/inactive/microcrystalline-cellulose-48.html

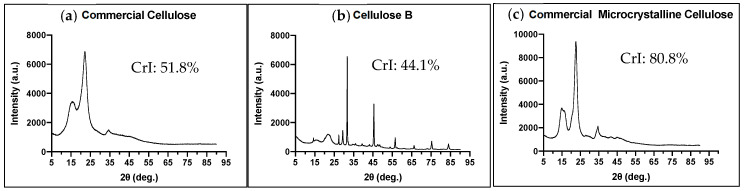

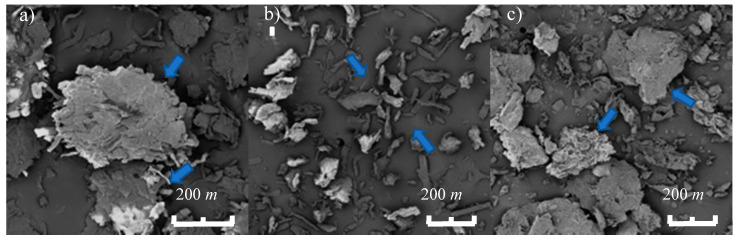

By treating wood pulp with mineral acids, we get MCC. This breaks the large cellulose fibers into small, crystalline structures.This process removes amorphous regions, leaving behind pure, crystalline cellulose. MCC is perfect for medicine because of its uniform particle size, high density, and low moisture.

Here are some of the key applications:

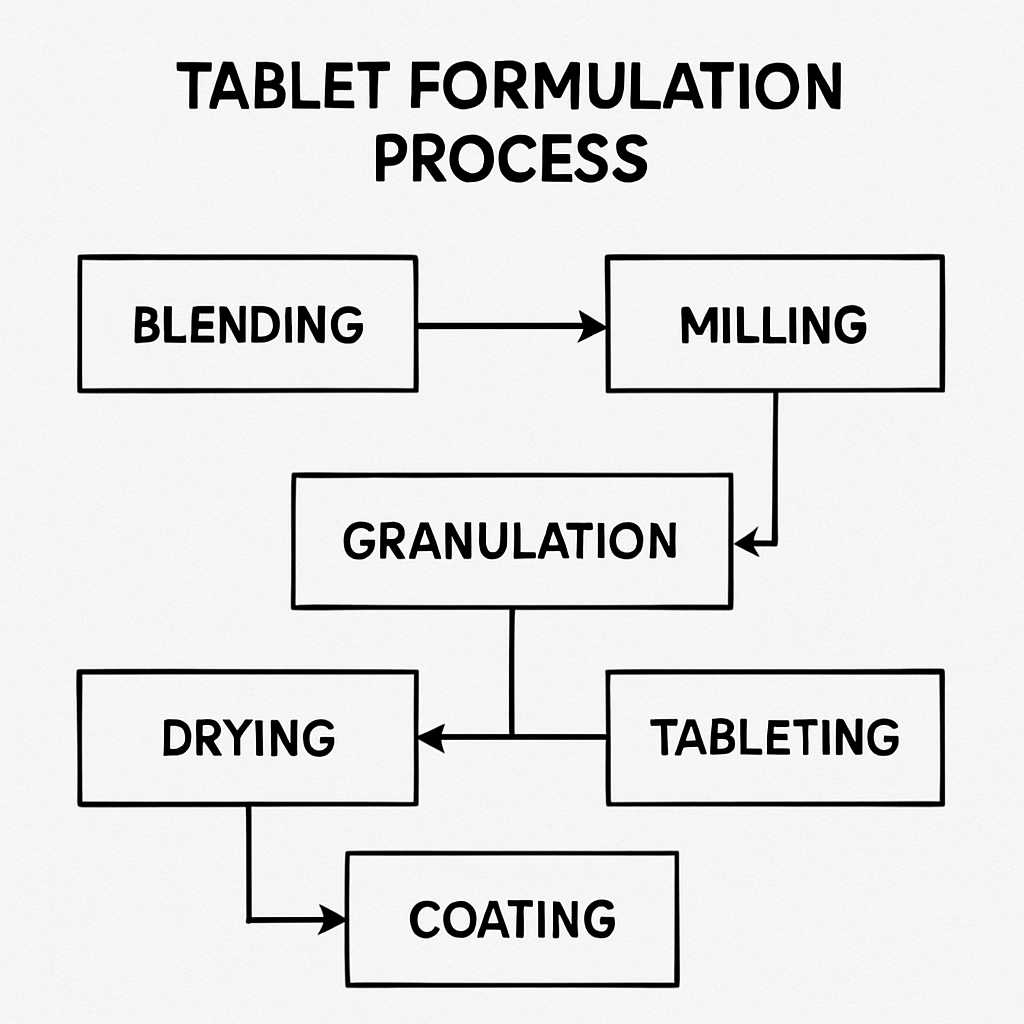

One of the primary uses of MCC is in tablet formulation. Its compressibility and binding properties make it an essential component in the production of tablets. It also helps them dissolve correctly in the body.

MCC is employed in various drug delivery systems, including sustained-release and controlled-release formulations. It does this because it is inert and can create a matrix, which helps a medication work consistently for a long time.

In addition to its role as a binder and filler, MCC is used as a coating agent. It makes tablets smooth and nice-looking, while protecting the ingredients from moisture and light.

This substance helps hide the bitter taste of some medicines. This makes them easier for people, especially kids and the elderly, to take.

The use of mcc in pharmaceuticals offers numerous advantages, contributing to its widespread adoption in the industry.

MCC enhances drug formulation by improving the fluidity and compressibility of powdered substances. This results in the production of high-quality tablets with consistent weight, hardness, and dissolution properties.

MCC is a cheap but effective excipient. This makes manufacturing simpler and costs less.

As a natural product derived from cellulose, MCC is harmless and safe for use in pharmaceutical applications. It does not react with other components in the formulation, ensuring the stability and efficacy of the final product.

For a product to stay popular for a long time, it has to work well, be reliable, and not too expensive. Discovered in 1955, MCC is now the most common binder used in the pharmaceutical industry. Its popularity comes from how versatile it is.

MCC can add volume, help a pill break apart, hold it together, and make it easy to press into shape. This multi-purpose nature makes it simpler to create new drugs and improves the final quality.

MCC also helps drugs stay stable and controls how fast they release into the body. This is crucial for medicines that need to work over a long period. This natural, fiber-rich compound is safe to chew, making it great for chewable and dissolvable pills.

MCC is also a key ingredient in supplements and in special drug systems, like medicated gels. Its wide range of uses and proven performance make it a cornerstone of modern medicine and health product manufacturing.

While MCC has many benefits, there are also some challenges to consider when using it in medicine.

Although MCC is relatively stable, it can be sensitive to moisture. Proper storage conditions and packaging are essential to maintain its integrity and prevent degradation.

Before using MCC, you need to test its fitness with the drug’s active ingredients. This is to ensure it doesn’t interfere with the drug’s effects or stability.

Manufacturers must ensure that the use of MCC complies with regulatory standards and guidelines for pharmaceutical excipients. This includes adhering to quality control measures and documenting the sourcing and processing of MCC.

MCC plays a vital role in the pharmaceutical industry, offering a range of benefits that enhance drug formulation and delivery. Its excellent compressibility, stability, and flexibility make it anessential excipient in tablet production and other pharmaceutical applications.

By understanding the properties and applications of MCC, pharmaceutical manufacturers can optimize their formulations, improve product quality, and ensure consistent therapeutic effects. As a valuable additive, MCC helps create effective and safe medications for patients worldwide.

MCC plays a vital role in the pharmaceutical industry, offering a range of benefits that enhance drug formulation and delivery. Its excellent compressibility, stability, and flexibility make it anessential excipient in tablet production and other pharmaceutical applications.

By understanding the properties and applications of MCC, pharmaceutical manufacturers can optimize their formulations, improve product quality, and ensure consistent therapeutic effects. As a valuable additive, MCC helps create effective and safe medications for patients worldwide.

In summary, the role of MCC in pharmaceuticals is many-sided, providing essential support in drug formulation and delivery. Its unique properties and advantages make it a cornerstone of the industry, driving innovation and improving patient outcomes.