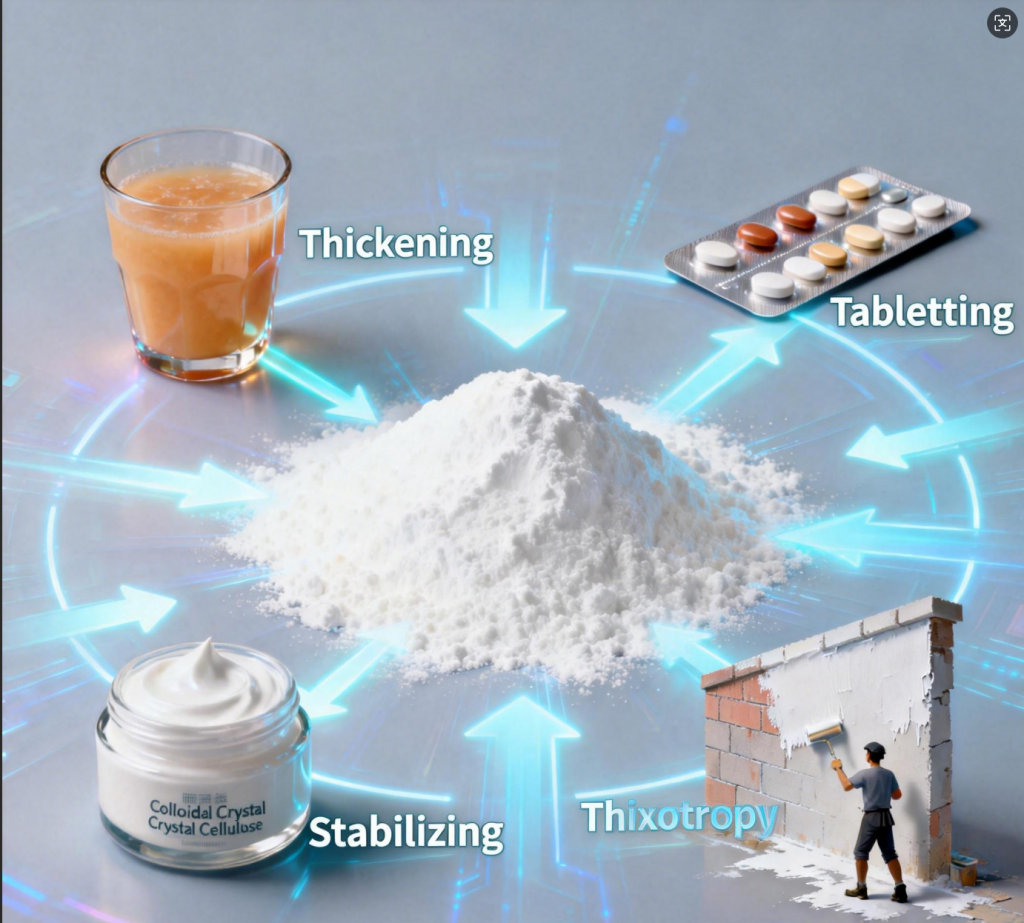

A new development in food technology, ACTA® Microcrystalline Cellulose for Food & Nutrition is a colloidal form that combines the benefits of pure MCC with the stabilizing power of CMC, achieved in a balanced 13:87 ratio.

This co-processed formulation works well as a fat replacer, anti-caking agent, bulking agent, and dietary fiber. Completely insoluble in water, it has zero calories. Qingdao ACTA Biotechnology produces 30,000 metric tons of microcrystalline cellulose each year.

They dedicate 3,000 metric tons to colloidal MCC. The company exports to over 80 countries. This makes them a top global supplier of this versatile plant fiber ingredient.

Colloidal MCC is different from standard microcrystalline cellulose. A special blend combines the best features of two cellulose types.

· Microcrystalline Cellulose (MCC): Provides structure, water-holding capacity, and fiber bulk

· Sodium Carboxy methyl cellulose (CMC): Delivers stabilization, mixing, and suspension properties

Critical Composition Data: Research shows that the best colloidal MCC formulations use weight ratios of MCC to CMC. These ratios range from about 50:50 to 95:5. ACTA’s special formulation uses a 13:87 MCC to CMC ratio. This ratio maximizes performance in many different applications.

Commercial colloidal MCC usually has an 80:20 mix of microcrystalline cellulose and carboxy methyl cellulose sodium. This mix shows great dispersion performance.

The production of high-quality ACTA® Microcrystalline Cellulose for Food & Nutrition requires sophisticated processing. The manufacturing process starts by mixing carboxy methyl cellulose with wet microcrystalline cellulose. Then, we extrude the mixture to ensure thorough mixing. Mechanical processing adds shearing forces to reduce the particle size to colloidal dimensions.

ACTA’s production infrastructure includes:

· ¥260 million (~$36 million USD) investment in state-of-the-art equipment

· €10 million (~$10.8 million USD) in imported, customized machinery meeting international standards

· 30,000 MT annual microcrystalline cellulose production capacity supported by ISO Class 5 cleanrooms

· 3,000 MT annual colloidal microcrystalline cellulose production capacity

· 54,760 m³/hour HEPA filtration systems ensuring pharmaceutical-grade purity

Molecular Structure: ACTA® colloidal MCC has the formula (C₆H₁₀O₅)ₙ. Its typical polymer weights are in the tens of thousands of g/mol. It appears as a white, almost odorless powder with 98% of particles passing through a 120-mesh sieve.

Key Properties:

· Water Absorption: Absorbs 4-9 times its own weight in water

· Bulk Density: Extremely low, ideal for volume enhancement

·absorb ability: Not digested by human cellulase enzymes—functions as inert dietary fiber

· Caloric Value: 0 kcal/g (zero calories)

The 13:87 MCC:CMC composition in ACTA’s colloidal formulation creates synergistic effects that surpass single-component systems:

Performance Metrics (measured as 2.6% dispersion in water):

· Gel Strength (G’): Achieves 9-15 Pa after 24-hour maturation—representing a 30-50% improvement over standard formulations

· Initial Viscosity: At least 750 cps (centipoise)

· Set-up Viscosity: Exceeds 3,200 cps

· Active Component Concentration: 15-20% higher than competing domestic and international products

As a fat mimetic, ACTA® colloidal MCC creates the sensory experience of fat without calories:

Quantified Benefits:

· Calorie Reduction: Enables up to 50% fat reduction in meat products while maintaining juiciness

· Optimal Dosage: 2% addition in meat formulations provides best sensory characteristics

Mouthfeel Simulation: The feel of MCC particles in the CMC network is like fat globules. This creates a creamy look and texture.

· Cost Advantage: 15-20% lower total cost of ownership compared to Western alternatives

In reduced-fat ice cream and whipped toppings, the colloidal structure gives a creamy feel. This happens through physical particle sensation, not chemical interaction. This makes it better than simple starch-based substitutes.

In shredded cheese, spice mixes, and powdered products:

Regulatory Compliance:

· Health Canada: Maximum 2.0% in cheese products (used alone or in combination)

· U.S. FDA: Up to 4% in general food products

· USDA: Maximum 3.5% in meat products

Mechanism: The water-absorbing capacity of colloidal MCC prevents moisture-induced clumping while maintaining product flow characteristics. Market studies show some cheese products contain up to 9% cellulose, though ACTA recommends staying within regulatory limits.

In liquid applications, ACTA® colloidal MCC demonstrates 30% stronger suspension performance than German and U.S. equivalents:

Application Dosages:

· Plant-based beverages: ~0.8% prevents protein settling and maintains consistency throughout shelf life

· Salad dressings: Stabilizes oil-in-water emulsions, preventing syneresis

· Sauces and dips: Provides shear-thinning behavior—high viscosity at rest, easy flow when poured

The colloidal network structure creates strong thickening with desirable rheological properties that surpass traditional gums and starches.

Zero-Net-Carb Profile: Unlike starch-based bulking agents, ACTA® Microcrystalline Cellulose for Food & Nutrition is:

· non-absorbable: Passes through the GI tract unchanged

· Keto-friendly: Suitable for low-glycemic index formulations

· Gluten-free: Provides structural support in gluten-free baking without contributing glycemic load

Flavor Neutrality: It is chemically inert and odorless. It adds texture without hiding delicate flavors or affecting vitamin enrichment. This is a key advantage over gum-based options.

As a 100% insoluble dietary fiber, ACTA® colloidal MCC provides multiple health benefits:

Gut processing Benefits:

· Promotes gut motility: Stimulates peristalsis, improving digestive function

· Prevents constipation: Adds bulk to stool

· Supports satiety: Expands in the stomach, creating fullness

Metabolic Effects:

Lipid processing: Research shows that MCC helps the digestive system. It also lowers lipids and affects enzymes that manage lipid processing.

· Blood sugar control: Delays carbohydrate absorption, reducing glycemic response

· Weight management: Increases satiety while adding zero calories

Daily Intake Context:

· Recommended adult fiber intake: At least 25 grams/day

· Average U.S. MCC consumption: 2.7 g/day (children) to 5.1 g/day (adult males)

· High consumers (90th percentile): 5.4-10.2 g/day

Zero Calories, Zero Sugars, Zero Gluten:

· Caloric density: 0 kcal/g—ideal for calorie-reduced formulations

Carbohydrates contribute zero net carbs since the body does not process fiber.

· Allergen status: Gluten-free, suitable for celiac disease and gluten sensitivity

· Sugar content: None—appropriate for diabetic formulations

ACTA® colloidal MCC’s engineered particle geometry improves manufacturing efficiency:

Flow Benefits:

· Reduces hopper bridging in automated equipment

· Ensures consistent weight consistency during high-speed packaging

· Minimizes dust generation compared to standard MCC

· Improves blending consistency in dry mix formulations

In bakery applications, ACTA® Microcrystalline Cellulose for Food & Nutrition offers superior performance:

· Water retention: Reduces staling by holding moisture in crumb structure

· Dough strengthening: Reinforces gluten-free formulations that lack wheat protein networks

· Oil uptake reduction: Lowers fat absorption in fried goods by reducing oil penetration

· Shelf-life extension: Maintains texture quality over extended storage

ACTA® colloidal MCC meets or exceeds international standards:

Regulatory Status:

· European Union: Approved as E460(i) per Commission Regulation (EU) No 231/2012

· United States: FDA GRAS (Generally Recognized as Safe) status

· International: FAO/WHO Joint Expert Committee: “Acceptable Daily Intake not specified”

Purity Specifications (per E460 standards):

· α-Cellulose content: ≥97% on dry basis

· Heavy metals limits:

o Arsenic: ≤3 mg/kg

o Mercury: ≤1 mg/kg

o Cadmium: ≤1 mg/kg

o Lead: ≤10 mg/kg

microbial Standards:

· Total plate count: ≤1,000 cfu/g

· Yeasts and molds: ≤100 cfu/g

toxicity-related Assessment:

· Acute toxicity: None observed at typical usage levels

· Skin/eye irritation: Non-irritant

· Laxative effects: Only at extremely high doses because of fiber bulk

· Allergenic potential: None reported

Manufacturing Certifications:

· ISO 9001:2015 (Quality Management)

· ISO 22000:2018 (Food Safety Management)

· Halal and Kosher certified

· FDA Master File registered

Qingdao ACTA Biotechnology operates as a vertically integrated manufacturer:

Facility Specifications:

· Founded: 2002 (over 20 years of expertise)

· Total microcrystalline cellulose production capacity: 30,000 metric tons annually

· Colloidal MCC production capacity: 3,000 metric tons annually dedicated to this flagship product line

· Quality infrastructure: Comprehensive testing suite featuring atomic absorption spectrometers, UV-Vis analyzers, and HPLC systems

Quality Consistency:

· Batch variation: <0.1% across production runs

· Environmental controls: ±0.5°C temperature, ±2% RH humidity monitoring

· eco-friendliness: 40% lower water consumption and 28% reduced carbon footprint versus industry averages

ACTA® products reach over 80 countries worldwide, with established presence in:

· Europe: Meeting stringent EU food safety standards

· North America: FDA-compliant formulations

· Southeast Asia: Halal-certified products

· Africa: Cost-effective solutions for emerging markets

· Middle East: Kosher and Halal certifications

Industry Trends:

· 2024 Global Market Size: $1.14 billion (fat replacer MCC gel segment)

· Projected CAGR: 6.8% through 2033

· 2033 Forecast: $2.09 billion total market value

Growth Drivers:

1. Increasing consumer health consciousness

2. Regulatory pressure for calorie reduction

3. Clean-label ingredient demand

4. Plant-based food expansion

5. Cost pressures driving fat replacement

Target Applications: Burger patties, sausages, meatballs, deli meats

Benefits:

· 50% fat reduction possible while maintaining sensory quality

· Enhanced juiciness and tenderness

· Improved binding and water retention

· Cost reduction through fat replacement

Recommended Dosage: 1.5-2.5% of total formulation

Target Applications: Low-fat ice cream, frozen yogurt, whipped toppings, processed cheese

Benefits:

· Creates creamy mouthfeel in reduced-fat formulations

· Prevents ice crystal growth in frozen products

· Acts as anti-caking agent in shredded/grated cheese (max 2.0%)

· Provides heat stability in processed cheese

Recommended Dosage: 0.5-1.5% in frozen desserts; up to 2.0% in cheese

Target Applications: Plant-based milks, protein shakes, fruit beverages, nutritional drinks

Benefits:

· Prevents protein settling with just 0.8% addition

· Creates uniform suspension throughout shelf life

· Provides smooth mouthfeel without grittiness

· Shear-thinning behavior for easy pouring

Recommended Dosage: 0.5-1.0% of total formulation

Target Applications: Gluten-free breads, low-fat cookies, cakes, filling creams

Benefits:

· Reinforces gluten-free dough structure

· Reduces oil uptake in fried goods

· Improves moisture retention for extended shelf life

· Lowers glycemic index in baked products

Recommended Dosage: 1.0-3.0% depending on application

Target Applications: Salad dressings, mayonnaise, ketchup, BBQ sauce, dips

Benefits:

· Stabilizes oil-in-water emulsions

· Prevents syneresis (liquid separation)

· Creates desirable viscosity profiles

· Extends shelf life through improved stability

Recommended Dosage: 0.3-1.0% of total formulation

Source: Knowde – MCC in Food Products

Performance Benchmarking:

· 30% stronger suspension vs. German/U.S. competitors

· 15-20% higher active components vs. market average

· 9-15 Pa gel strength (30-50% improvement over standard)

· Superior batch consistency (<0.1% parameter variation)

Economic Benefits:

· 15-20% lower total cost of ownership compared to Western suppliers

· Competitive pricing without compromising quality

· Reduced waste through enhanced stability

· Lower usage rates because of superior functionality

Environmental Performance:

· 40% lower water consumption in manufacturing

· 28% reduced carbon footprint

· Plant-based, renewable raw materials

· breakable end product

Value-Added Services:

· Technical formulation assistance

· Custom blend development

· Application testing support

· Multi-language customer service

For Food Manufacturers: ✓ Proven track record: 20+ years of manufacturing excellence

✓ Global scale: 30,000 MT MCC capacity, 3,000 MT colloidal MCC capacity, 80+ country distribution

✓ Quality assurance: ISO 9001, ISO 22000, Halal, Kosher certified

✓ Technical innovation: 13:87 MCC:CMC formulation

✓ Cost benefit: 15-20% savings vs. Western alternatives

✓ eco-friendliness: 40% water savings, 28% carbon reduction

For Product Development Teams: ✓ unique edge: Fat replacer + stabilizer + bulking agent + fiber

✓ Clean label: Simple ingredient declaration (E460i/MCC)

✓ Allergen-free: Gluten-free, non-GMO, vegan

✓ Zero calories: Enables calorie reduction claims

✓ Flavor neutral: Doesn’t mask product taste profiles

For Health-Conscious Brands: ✓ Dietary fiber: Contributes to daily fiber intake

✓ Glycemic control: Lowers GI of finished products

✓ Satiety enhancement: Supports weight management claims

✓ Gut health: Promotes digestive wellness

Active Packaging: Research explores MCC-based films with:

· Enhanced barrier properties

·germ-resistant functionality

· Extended shelf-life capabilities

nano-structured Cellulose: Next-generation derivatives with:

· Even smaller particle sizes

· Enhanced functional properties

· Novel applications in food and pharma

Customized Blends: ACTA continues developing:

· Application-specific MCC:CMC ratios

· Specialty grades for unique challenges

· Combination products with other hydrocolloids

ACTA® colloidal microcrystalline cellulose represents the convergence of advanced materials science, food technology, and sustainable manufacturing. ACTA has improved a adaptability ingredient. They did this by mixing microcrystalline cellulose and CMC in a 13:87 ratio.

· Reduces calories without compromising taste or texture

· Enhances nutritional profiles through dietary fiber addition

· Improves manufacturing efficiency with better flow properties

· Meets global regulatory standards with exceptional purity

· Delivers cost savings through superior functionality

Qingdao ACTA Biotechnology has a production capacity of 30,000 metric tons of microcrystalline cellulose each year. They produce 3,000 metric tons of colloidal MCC. They distribute their products to over 80 countries.

ACTA is ready to partner with food manufacturers around the world. They offer innovative, cost-effective, and sustainable solutions.

The benefit of colloidal is clear: When you choose ACTA®, you are not just buying an ingredient. You have twenty years of manufacturing experience. You also get high-quality systems. A global support network focuses on your product’s success.

Ready to experience the ACTA® difference?

Qingdao ACTA Biotechnology Co., Ltd.

Founded: 2002

Microcrystalline Cellulose Production Capacity: 30,000 MT/year

Colloidal MCC Production Capacity: 3,000 MT/year

Export Markets: 80+ countries

Website: https://www.actabiotechnology.com

Product Information: ACTA Colloidal MCC for Food

1. Google Patents – Stabilizer Composition of MCC and CMC: https://patents.google.com/patent/WO2013052114A1/en

2. ScienceDirect – MCC-CMC as Effective Dispersant: https://www.sciencedirect.com/science/article/abs/pii/S0144861715009042

3. FMC Corporation Patent – MCC:CMC Stabilizer: https://www.freepatentsonline.com/y2018/0042283.html

4. WHO Food Additives Series 40 – MCC Intake Data: https://www.inchem.org/documents/jecfa/jecmono/v040je03.htm

5. PubMed – Functionality and Nutritional Aspects of MCC: https://pubmed.ncbi.nlm.nih.gov/28606522/

1. ScienceDirect – Fat Replacement in Meat Products: https://www.sciencedirect.com/science/article/abs/pii/S0268005X14004317

2. PMC – MCC as protector Dietary Fiber: https://pmc.ncbi.nlm.nih.gov/articles/PMC10468960/

3. Knowde – MCC in Food Products: https://periodical.knowde.com/microcrystalline-cellulose-in-food-products/

1. Health Canada – Anticaking Agents in Cheese: https://www.canada.ca/en/health-canada/services/food-nutrition/public-involvement-partnerships/modification-permitted-anticaking-agents-cellulose-cheese.html

2. WHO Food Additives Series – Safety Assessment: https://inchem.org/documents/jecfa/jecmono/v08je08.htm

3. Wikipedia – Microcrystalline Cellulose: https://en.wikipedia.org/wiki/Microcrystalline_cellulose

1. USDA – Cellulose Handling/Processing Report: https://www.ams.usda.gov/sites/default/files/media/Cellulose_TR%202_11_2016.pdf

2. BulkSupplements – MCC Comprehensive Guide: https://community.bulksupplements.com/microcrystalline-cellulose/

1. ACTA – Colloidal MCC for Food Applications: https://www.actabiotechnology.com/acta-brand-colloidal-microcrystalline-cellulose-for-food/

2. ACTA – Product Overview Multi-Industry: https://www.actabiotechnology.com/product/colloidal-microcrystalline-cellulose-for-food-pharma-chemical/

3. ACTA – About Us: https://www.actabiotechnology.com/about-us/

4. ACTA – High-Quality MCC Gel Production: https://www.actabiotechnology.com/high-quality-excited-price-mcc-gel-from-qingdao-acta/

5. ACTA – MCC Gel Manufacturers: https://www.actabiotechnology.com/microcrystalline-cellulose-gel-manufacturers-trusted-supplier/

1. Growth Market Reports – Fat Replacer MCC Gel Market: https://growthmarketreports.com/report/fat-replacer-microcrystalline-cellulose-gel-market/amp

2. Healthline – Cellulose Fiber Safety: https://www.healthline.com/nutrition/cellulose-fiber