In the fast-changing world of food technology, ACTA®Colloidal Microcrystalline Cellulose for Food(CMCC) has become a key ingredient. It successfully combines natural, clean-label appeal with high-performance results.

Produced by Qingdao ACTA Biotechnology Co., Ltd., ACTA® has been a top manufacturer in China since 2002. It shows over 20 years of experience. The company specializes in perfecting food-grade cellulose that meets and surpasses global standards.

This guide explains the science, uses, and strengths of ACTA® Colloidal MCC. It shows why food developers worldwide rely on it to create innovative, health-focused, and cost-efficient products.

Colloidal microcrystalline cellulose (MCC) is a sophisticated powdered blend of microcrystalline cellulose and sodium carboxy methyl cellulose (CMC-Na) engineered specifically for food formulations. Specialized technology improves the colloidal form of microcrystalline cellulose. This creates a system that mixes better and performs well compared to the standard version.

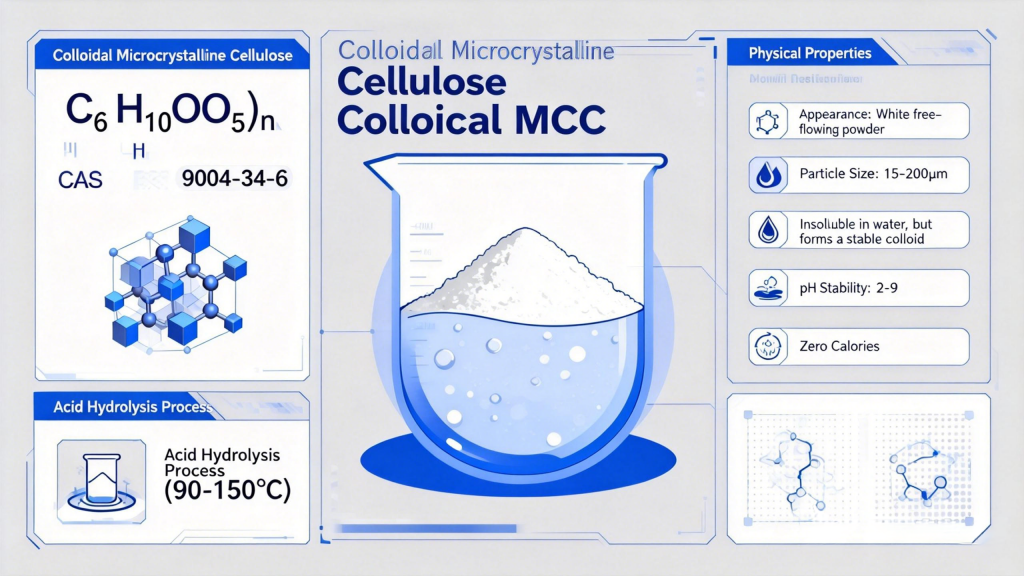

ACTA® Colloidal Microcrystalline Cellulose for Food is a purified form of cellulose. Partially broken down, it has the molecular formula (C₆H₁₀O₅)ₙ. Its CAS number is 9004-34-6.

We make ACTA®Colloidal Microcrystalline Cellulose for Food using acid hydrolysis of alpha-cellulose at temperatures from 90 to 150°C. This process removes the amorphous regions of the fibers, leaving behind a crystalline structure.

ACTA®Colloidal Microcrystalline Cellulose for Food represents an advanced engineering achievement: manufacturers combine microcrystalline cellulose with sodium carboxymethylcellulose and carefully control the particle size distribution. This makes a material that spreads evenly in water. ACTA® Colloidal Microcrystalline Cellulose for Food forms stable suspensions and gels while keeping the good properties of both parts.

ACTA®Colloidal Microcrystalline Cellulose for Food exhibits:

Chemical Inertness: ACTA®Colloidal Microcrystalline Cellulose for Food does not react with other food ingredients or processing conditions

Appearance: White to off-white, free-flowing powder

Particle Size: Carefully controlled distribution optimized for food applications (typically 15-200 micrometers)

Dissolving ability: Insoluble in water but forms stable colloidal suspensions

pH Stability: Stable across pH 2-9, making ACTA® Colloidal Microcrystalline Cellulose for Food versatile for acidic to neutral food systems

Caloric Value: Zero digestible calories (ACTA® Colloidal Microcrystalline Cellulose for Food acts as insoluble dietary fiber)

Qingdao ACTA Biotechnology Co., Ltd. was established in 2002 and has grown to become one of China’s largest manufacturers of ACTA®Colloidal Microcrystalline Cellulose for Food. With more than 20 years of experience producing ACTA®Colloidal Microcrystalline Cellulose for Food, the company is a key player in the global cellulose market.

ACTA has created a smart and automated system for producing ACTA®Colloidal Microcrystalline Cellulose for Food with strict quality control. This system ensures that each batch of ACTA®Colloidal Microcrystalline Cellulose for Food is safe, effective, stable, and easy to manage. This integrated approach represents a significant advancement over traditional batch processing methods.

The company’s production facility for ACTA®Colloidal Microcrystalline Cellulose for Food is built to international standards, featuring:

ACTA operates under a comprehensive quality management system with multiple international certifications:

This certification portfolio shows ACTA’s commitment to high international standards for ACTA® Colloidal Microcrystalline Cellulose for Food in both food and pharmaceutical uses. It allows the company to confidently serve various global markets.

ACTA has implemented a dual-market development strategy, simultaneously targeting domestic Chinese markets and international markets. This global marketing approach helps ACTA® Colloidal Microcrystalline Cellulose for Food get constant feedback. This feedback leads to improvements based on different needs around the world.

The company’s ACTA® Colloidal Microcrystalline Cellulose for Food quality meets top international standards. Its performance matches or surpasses similar global products. This success is what the company calls “technological leadership” in the industry.

International Regulatory Approvals

ACTA®Colloidal Microcrystalline Cellulose for Food is based on microcrystalline cellulose E460(i), which enjoys broad regulatory acceptance:

European Union:

EFSA Conclusion: “There is no need for a specific ADI (Acceptable Daily Intake).” They also state, “There are no safety concerns at the reported uses and levels.”

JECFA (Joint FAO/WHO Expert Committee on Food Additives) gives ACTA®Colloidal Microcrystalline Cellulose for Food for Food an ADI of “not specified.” This means it has extremely low toxicity at levels needed for its use.

ACTA emphasizes that ACTA® Colloidal Microcrystalline Cellulose for Food is pure and plant-based, with the body neither digesting nor absorbing it. It behaves as a low-calorie, inert additive in the digestive tract, acting primarily as bulk fiber.

At typical usage levels (0.2-2.5% depending on application), ACTA® Colloidal Microcrystalline Cellulose for Food presents no safety concerns. At high amounts, it can have a mild laxative effect. This is because it acts like fiber and does not digest.

ACTA® Colloidal Microcrystalline Cellulose for Food serves multiple critical functions simultaneously, making it an economical and efficient choice for food manufacturers:

ACTA® Colloidal Microcrystalline Cellulose for Food is a strong texture modifier and thickener. It improves mouthfeel and creaminess in many applications. ACTA says ACTA® Colloidal Microcrystalline Cellulose for Food mixes with water to create a colloidal system. This system offers strong thickening and stabilizing effects, even in small amounts.

Key benefits:

Applications: Beverages, sauces, dairy products, and baked goods where smooth texture is critical.

One of the best features of ACTA® Colloidal Microcrystalline Cellulose for Food is its strong ability to stabilize and suspend. It helps stop phase separation in emulsions and liquid foods.

Performance Data from ACTA Case Studies:

ACTA® Colloidal Microcrystalline Cellulose for Food forms a weak gel network. This network shows thixotropic behavior. You can keep it suspended during storage, but you can make it flow freely by shaking or pouring it. This ensures a great experience for consumers.

ACTA highlights ACTA® Colloidal Microcrystalline Cellulose for Food as an “excellent fat mimetic” in low-calorie formulations. ACTA® Colloidal Microcrystalline Cellulose for Food can replace fat in low-fat or reduced-calorie foods. It mimics the feel of fat by binding water and forming gels.

Functional mechanisms:

This ability of ACTA® Colloidal Microcrystalline Cellulose for Food is especially useful in dairy products, salad dressings, baked goods, and processed meats. It allows for fat reduction without losing taste and quality.

ACTA® Colloidal Microcrystalline Cellulose for Food can serve as an effective carrier for flavors, colors, vitamins, minerals, and other functional ingredients, ensuring even distribution throughout food matrices.

Benefits of ACTA® Colloidal Microcrystalline Cellulose for Food as a carrier:

Nutritional benefits of ACTA® Colloidal Microcrystalline Cellulose for Food:

ACTA calls ACTA® Colloidal Microcrystalline Cellulose for Food a “sensory-neutral dietary fiber addition.” It does not change flavor or appearance. This makes it great for adding fiber to foods.

ACTA® Colloidal Microcrystalline Cellulose for Food is useful in frozen desserts and protein-rich drinks. It helps with food texture and stability. Its ability to bind water and thixotropic properties make it especially effective.

Frozen dessert applications with ACTA® Colloidal Microcrystalline Cellulose for Food:

Protein beverage applications with ACTA® Colloidal Microcrystalline Cellulose for Food:

Creates desirable viscosity and body

Prevents protein settling and sedimentation

Masks chalky mouthfeel of some protein sources

Improves stability at various pH levels

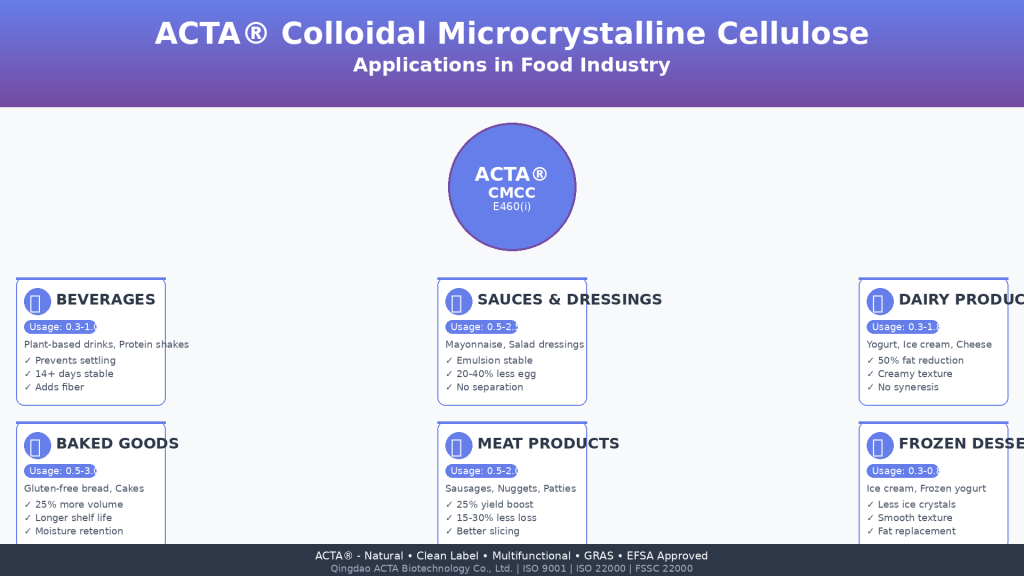

Beverages: Dairy, Plant-Based, and Functional Drinks

ACTA clearly states that beverages are a main use for its colloidal MCC. It works as a stabilizer, thickener, suspending agent, and texture enhancer.

– Usage Level: 0.3-0.8%

– Function: Stabilizes protein suspensions, prevents separation, creates desired viscosity

– Performance: In ACTA’s documented case studies, 0.8% colloidal MCC significantly reduced protein settling over 14+ days

– Benefits: Clean label, adds dietary fiber, improves mouthfeel

– Usage Level: 0.4-1.0%

– Function: Suspends protein powder and nutrients, prevents settling

– Benefits: Smooth, creamy texture; masks chalky aftertaste; stable across pH variations

– Case Study Result: Zero settling after 12 months storage in ready-to-drink format

– Usage Level: 0.5-1.0%

– Function: Keeps cocoa particles suspended, improves body

– Benefits: Uniform color and flavor, no settling, enhanced creaminess

– Usage Level: 0.2-0.6%

– Function: Suspends vitamins, minerals, herbs, and other active ingredients

– Benefits: Even distribution, improved stability, added fiber content

Sauces, Salad Dressings, and Condiments

ACTA mentions that sauces and salad dressings are key uses for colloidal MCC. It helps stabilize oil-in-water systems and control thickness.

– Usage Level: 0.5-2.5%

– Function: Emulsion making stable, fat replacement, viscosity control

– Performance: Can reduce egg yolk requirements by 20-40%

– Benefits: Extends shelf life, prevents oil separation, supports clean label

Vinaigrettes and Light Dressings:

– Usage Level: 0.3-1.5%

– Function: Suspension of herbs and spices, viscosity building

– Benefits: Stable suspension, pourable consistency, no synthetic thickeners

– Usage Level: 0.4-1.2%

– Function: Thickness enhancement, prevention of water separation

– Benefits: Improved cling to food, clean label alternative to modified starches

– Usage Level: 0.6-2.0%

– Function: Fat replacement, thickness, stability

– Benefits: Reduced calorie content, maintained richness

Low-Fat Yogurt:

– Usage Level: 0.5-1.5%

– Function: Prevents syneresis (water separation), improves mouthfeel

– Benefits: Creamy texture despite reduced fat, extended shelf life

– Performance: Colloidal MCC forms stable gel structure that mimics fat

– Usage Level: 0.3-1.0%

– Function: Water binding, texture improvement

– Benefits: Reduced fat while maintaining spread ease

– Usage Level: 0.5-1.8%

– Function: making stable of protein, thickness, texture

– Benefits: Comparable mouthfeel to dairy yogurt, prevents phase separation

– Usage Level: 0.3-0.8%

– Function: Ice crystal control, fat replacement, stability

– Benefits: Smooth texture, reduced fat (up to 50%), improved freeze-thaw stability

– Performance: ACTA notes that colloidal MCC helps maintain smooth texture and reduces ice crystal formation

Gluten-Free Bread and Baked Goods:

– Usage Level: 1.0-3.0% of flour weight

– Function: Partial replacement of gluten’s structural functions

– Benefits: Improved water binding, enhanced volume, extended shelf life

– Performance Data: Volume can increase by 25%, shelf life extended from 3 to 5 days

– Usage Level: 0.5-2.0%

– Function: Partial sugar and fat replacement, moisture retention

– Benefits: Reduced calories, maintained volume and texture, added fiber (up to 5g per serving)

Protein Bars and Energy Bars:

– Usage Level: 1.0-4.0%

– Function: Binding of ingredients, texture creation

– Benefits: Prevents separation in layered products, desired chewiness, sugar-free formulation support

Reformed Meat Products (nuggets, patties, sausages):

– Usage Level: 0.5-2.0%

– Function: Water and fat binding, texture improvement

– Performance: Up to 25% improvement in yield, 15-30% reduction in purge loss

– Benefits: Fat reduction while maintaining juiciness, improved slicing characteristics

– Usage Level: 0.3-1.0% in breading

– Function: Adhesion of breading to substrate

– Benefits: Reduced moisture loss during cooking, crispy texture maintenance

Controlled Particle Size Distribution

ACTA emphasizes that its colloidal MCC features high purity and controlled particle size as key Unique points. The company’s automated production system ensures that particle sizes are consistent in each batch. This is important for predictable viscosity, suspension capacity, and gel behavior in large-scale food production.

Particle size optimization provides:

– Predictable Viscosity: Consistent thickness across production batches

– Superior Suspension: Uniform distribution of insoluble particles

– Smooth Mouthfeel: No grittiness or unpleasant texture

– Enhanced Functionality: Optimal performance in specific applications

Batch Consistency and Quality Control

ACTA’s advanced quality control system ensures that batch products are safe, effective, stable, and controllable. The company materials claim that ACTA strives to “exceed some industry standards,” translating into:

– Consistent functional performance across production lots

– Minimal batch-to-batch variation in viscosity and gel strength

– Reliable suspension and making stable properties

– Predictable interaction with other ingredients

This consistency is essential for food manufacturers operating at industrial scale, where formulation difference can lead to quality issues and production losses.

ACTA positions its colloidal MCC as a high-quality, affordably priced alternative to top international brands. While specific food industry data is private, ACTA shows cost benefits in pharm uses. For example, there is a 23% cost reduction in some tablet production cases. This suggests that food formulations, which are sensitive to costs, may also have similar value.

Cost advantages stem from:

– Multi-use: Replaces 2-4 separate ingredients (stabilizer, thickener, suspending agent, fat replacer)

– Efficient Production: Advanced manufacturing reducing unit costs

– Reduced Usage Levels: Strong effects even at small amounts (0.2-2.5%)

– Extended Shelf Life: Prevents product spoilage and waste

Formulation Guidelines and Best Practices

Proper hydration is critical for optimal performance of ACTA® Colloidal MCC:

Dry Blending Method (for powders and dry mixes):

1. Pre-blend ACTA® with other dry ingredients (ratio 3-5:1)

2. Add blend to liquid phase under high shear mixing

3. Mix for 10-20 minutes to ensure complete hydration

4. Allow to rest for 30-60 minutes for full gel development

Slurry Method (for liquid applications):

1. Disperse ACTA® in water at 1:10 to 1:20 ratio

2. Mix under high shear for 5-10 minutes

3. Add slurry to main formulation

4. Continue mixing until uniform distribution achieved

Hot Process Applications:

1. Disperse in cold water first (prevents clumping)

2. Heat gradually to required temperature (stable up to 95°C)

3. ACTA® maintains stability even during prolonged boiling

pH Stability Across Food Systems

ACTA® Colloidal MCC demonstrates excellent stability across a wide pH range, making it versatile across diverse food categories:

– pH 2-3 (Highly Acidic): Stable in fruit beverages, dressings with vinegar, citrus products

– pH 4-6 (Slightly Acidic): Optimal performance in most food applications including tomato products, yogurt

– pH 7-9 (Neutral to Alkaline): Stable in dairy products, meat applications, some bakery goods

Unlike some hydrocolloids that precipitate or lose functionality at extreme pH values, ACTA® maintains consistent performance across this range.

Source: https://proe.info/en/additives/e460i

ACTA® Colloidal MCC works working together with other hydrocolloids, allowing for reduced total usage levels and enhanced functionality:

With Xanthan Gum:

– Enhanced suspension stability in beverages

– Improved freeze-thaw resistance in frozen products

– Better mouthfeel in low-fat applications

– Typical ratio: 2-3 parts ACTA® to 1 part xanthan gum

With Carrageenan:

– Stronger gels in dairy applications

– Reduced syneresis in yogurt and cheese

– Improved protein making stable in plant-based products

– Ratio: 1:1 to 3:1

With Guar Gum or Locust Bean Gum:

– Enhanced viscosity in sauces and dressings

– Improved texture in ice cream

– Better freeze-thaw stability

– Synergistic gel formation

Clean Label and Consumer Trends

ACTA highlights that its colloidal MCC is “pure” and “plant-based.” This fits well with today’s clean label and natural product trends.

Clean Label Benefits:

– Recognized as “cellulose,” “plant fiber,” or “microcrystalline cellulose” on ingredient lists

– Derived from renewable plant sources (wood pulp)

– No chemical alteration beyond cleaning

– Non-GMO options available

– Can support organic product claims (where certified)

Consumer-Friendly Attributes:

– Vegan and plant-based: No animal-derived components

– Allergen-Free: Gluten-free, dairy-free, soy-free, nut-free

– Halal and Kosher: Certified options available

– Known Name: Consumers increasingly familiar with “cellulose” and “fiber”

MCC’s functional wide use supports calorie-reduction strategies in product design while maintaining acceptable sensory quality. ACTA® Colloidal MCC helps food companies. This ingredient can serve as a partial substitute for fats and sugars.

This substitution is efficient in calories. . ACTA® Colloidal MCC is a zero-calorie fiber. This helps them meet consumer demand for healthier options while keeping taste and texture.

Typical calorie reductions achievable:

– Low-Fat Dairy: 30-50% fat reduction with maintained creaminess

– Reduced-Calorie Dressings: 40-60% calorie reduction

– Light Baked Goods: 20-40% calorie reduction through fat and sugar replacement

– Diet Ice Cream: 50% or more fat reduction

Lasting and Environmental Benefits

ACTA’s commitment to environment-friendly production design supports lasting:

– Sourced from sustainably managed forests

– Nature-breakdown and compostable end-of-life

– Lower carbon footprint than synthetic alternatives

– Renewable resource base

– Supports circular economy principles

Comparative Advantages Over Alternative Ingredients

ACTA® Colloidal MCC advantages:

– Clean Label: “Cellulose” vs. “modified starch” (E-numbers)

– Calorie Content: 0 cal/g vs. 4 cal/g

– pH Stability: Wider range (pH 2-9) vs. limited stability for many starches

– Temperature Stability: No starch hardening or breakdown

– Freeze-Thaw: Superior stability in frozen applications

– Consumer Perception: More natural, less processed image

ACTA® Colloidal MCC benefits:

– Natural Origin: Plant-based vs. synthetic production

– Multi-use: Emulsifying + thickening + stabilizing + fiber provision

– Clean Label: Recognized as food, not just additive

– Consumer Trust: Better alignment with “real food” trends

– Regulatory: No E-number concerns in some markets

Versus Standard Microcrystalline Cellulose

ACTA® Colloidal MCC vs. regular MCC:

– Mixing ability: Superior ease of hydration and uniform distribution

– Emulsion Stability: Enhanced Stabilizing of oil-in-water systems

– Suspending Power: Better maintenance of particle suspension

– Texture: Smoother mouthfeel and creaminess

– Efficiency: Lower usage levels achieve same effects (30-50% reduction possible)

Versus CMC (Carboxy methyl cellulose) Alone

Colloidal MCC advantages:

– Binding Capacity: Superior water and fat binding

– Structure Formation: Better gel structure and body

– Anti-Caking: Enhanced free-flow properties in powders

– pH Range: Better performance in neutral to acidic systems

– Fiber Content: Higher contribution to dietary fiber

Physical Properties of ACTA® Colloidal MCC:

– Appearance: White to off-white, free-flowing powder

– Particle Size: Controlled distribution (specifications vary by grade)

– Bulk Density: 0.3-0.5 g/mL

– pH (1% suspension): 5.0-7.5

– Moisture Content: ≤7%

Chemical Specifications:

– Cellulose Content: ≥97% on dry basis

– Heavy Metals: <10 ppm

– Arsenic: <3 ppm

– Lead: <2 ppm

– Purity: Exceeds standard requirements per company claims

Germ-related Standards:

– Total Plate Count: <1,000 CFU/g

– Yeast and Mold: <100 CFU/g

– E. coli: Negative per test

– Salmonella: Negative in 25g

– Coliforms: <10 CFU/g

Functional Testing:

– Water binding capacity measurement

– Gel strength evaluation

– Particle size distribution by laser diffraction

– Viscosity profiling at various concentrations

– Emulsion stability testing

– Suspension capacity evaluation

Storage and Handling

Optimal Storage Conditions:

– Store in cool, dry location (below 25°C/77°F)

– Relative humidity: <65%

– Protect from direct sunlight and moisture

– Keep containers tightly closed when not in use

– Shelf life: 36 months under proper storage conditions

Handling Precautions:

– Use dust collection or ventilation systems to minimize airborne particles during handling

– While non-toxic, avoid prolonged inhalation of cellulose dust

– Use standard food-grade handling and hygiene practices

– Compatible with stainless steel, plastic, and glass processing equipment

– Ground equipment when handling large quantities to prevent static buildup

Case Study 1: Plant-Based Protein Beverage Making stable

Challenge:

A plant-based beverage manufacturer struggled with protein settling in their almond-pea protein blend drink. Consumers reported significant settling after just 3-5 days of storage, requiring vigorous shaking and resulting in poor sensory experience.

Solution:

We used 0.8% ACTA® Colloidal MCC as the main stabilizing and suspending agent. This helped improve dispersion by using high-shear mixing during production.

Results:

– Protein settling reduced by >90% over 14-day storage period

– Shelf life extended from 5 days to 21 days with minimal settling

– Smooth, creamy mouthfeel achieved without adding gums

– Added 1.6g dietary fiber per 200ml serving

– Clean label maintained (only “microcrystalline cellulose” added)

– Consumer acceptance scores improved from 6.2/10 to 8.4/10

Case Study 2: Low-Fat Salad Dressing

Challenge:

Develop a reduced-calorie ranch dressing with 50% less fat while maintaining creamy texture, emulsion stability, and consumer appeal.

Solution:

– Formulated with 1.8% ACTA® Colloidal MCC as fat replacer and emulsion stabilizer

– Reduced oil content from 60% to 30%

– Combined ACTA® with small amount of xanthan gum (0.3%) for synergy

Results:

– 45% total calorie reduction (from 450 cal/100g to 248 cal/100g)

– Stable emulsion with no oil separation after 6 months storage

– Viscosity and pour ease comparable to full-fat version

– Sensory panel rated texture as “Same-looking” from original

– Production cost reduced by 18% because of lower oil content.

– Clean label positioning achieved

Case Study 3: Gluten-Free Artisan Bread

Challenge:

Create a gluten-free bread with volume, crumb structure, and shelf life comparable to wheat bread.

Solution:

– Mixed in 2.5% ACTA® Colloidal MCC (based on total flour weight)

– Combined with psyllium husk (1.5%) and xanthan gum (0.8%)

– Modified hydration levels and mixing procedures

Results:

– Loaf volume increased by 28% compared to control without MCC

– Crumb structure significantly improved with smaller, more uniform air cells

– Shelf life extended from 3 days to 6 days before staling

– Moisture retention improved by 35% over 5-day storage period

– Consumer acceptance scores: 8.1/10 vs. 6.3/10 for control

– Successfully marketed as “high fiber” (4g per slice)

Emerging Applications

The role of ACTA® Colloidal MCC continues to expand into new territories:

Plant-Based Meat Alternatives:

– Critical binder in plant protein formulations

– Texture Alteration to mimic meat fiber structure

– Fat replacement while maintaining juiciness

– Water binding in burger patties and sausages

Personalized Nutrition:

– Carrier for customized vitamin and mineral blends

– Support for precision dosing in functional foods

– Tiny coating applications

3D Food Printing:

– Rheology modifier for printable food systems

– Structure formation in printed protein foods

– Support material for complex geometries

Clean Label Recipe changes:

– Replacement for synthetic emulsifiers and stabilizers

– Natural alternative to modified starches

– Making simple of ingredient lists

Functional Fiber Enhancement:

– Prebiotic property development

– Combination with probiotics for synbiotic foods

– Gut health positioning

Sustainable Packaging Integration:

– Bio-based coatings and films using cellulose

– Edible packaging applications

– Active packaging with germ-fighting properties

ACTA’s Comprehensive Support

As a major manufacturer with over 20 years of experience, ACTA Biotechnology provides technical support to help customers optimize formulations:

Application Development Services:

– Customized formulation assistance for specific products

– Pilot plant trials and scale-up support

– Process optimization recommendations

– Troubleshooting of production issues

Testing-related Services:

– Texturing and rheology profiling

– Stability testing (shelf life, temperature, pH)

– Sensory evaluation support

– Regulatory documentation assistance

Training and Education:

– On-site technical training for production staff

– Webinars on application best practices

– Technical bulletins and application guides

– Access to formulation databases and examples

Global Distribution Network:

With a globalized marketing strategy targeting both domestic and international markets, ACTA ensures reliable supply and support worldwide.

ACTA® Colloidal Microcrystalline Cellulose combines the appeal of natural ingredients, versatile performance, and cost-effectiveness. These three factors are important in today’s food formulation choices.

Key Strategic Advantages:

1. Proven Safety and Regulatory Acceptance: EFSA has decided that no ADI is needed. JECFA also gave ACTA® Colloidal MCC a “not specified” ADI. This means it has one of the best safety profiles among food additives.

2. Many uses Value: ACTA® acts as a texture modifier, thickener, stabilizer, suspending agent, fat replacer, and fiber source. This simplifies recipes and lowers ingredient costs.

3. Clean Label Alignment: ACTA® is a plant-based, non-GMO, and allergen-free ingredient. It has a name that people recognize. This supports the clean label trend that consumers want more and more.

4. Manufacturing Excellence: Qingdao ACTA Biotechnology has advanced production capabilities and many quality certifications. These include ISO 9001, ISO 22000, FSSC 22000, and EXCIPACT GMP. With over 20 years of experience, customers can trust in consistent quality and reliable supply.

5. Calorie-Reduction Helper: Today, many people value their health. ACTA® enables the reduction or removal of fat and sugar in food formulations.. It keeps the taste good, making it essential for creating lower-calorie products.

6. Cost-Effectiveness: Competitive pricing combined with many uses benefits and reduced usage levels translates to significant cost advantages for food manufacturers.

7. ACTA® Colloidal MCC is suitable for a broad range of food applications. Suitable for a wide range of applications, including beverages, baked goods, dairy products, and processed meats. This gives formulators a reliable solution for all their needs.

As consumers want more natural, healthy, and sustainable food, ingredients like ACTA® Colloidal Microcrystalline Cellulose will become more important. The company’s commitment to technological leadership—achieving or exceeding international product standards—positions ACTA® as a premier choice for food manufacturers worldwide.

Food scientists can use ACTA® Colloidal MCC for many purposes. They can create new plant-based drinks or change classic recipes to have fewer calories. This ingredient helps meet the needs for performance, safety, and clean labels in today’s food products.

With over two decades of specialized production experience, international quality certifications, and a global distribution strategy, Qingdao ACTA Biotechnology Co., Ltd. stands as a trusted partner for food manufacturers seeking to innovate with confidence.

—

1. ACTA Brand Colloidal Microcrystalline Cellulose for Food:

2. ACTA Colloidal MCC Product Specifications:

3. ACTA Case Studies and Supplier Information:

5. ProE.info – E460(i) Microcrystalline Cellulose Regulatory and Functional Data:

https://proe.info/en/additives/e460i

6. ScienceDirect – Microcrystalline Cellulose in Food Applications (Technical Chapter):

https://www.sciencedirect.com/science/chapter/edited-volume/abs/pii/B9781845694142500278

7. EU Regulation No. 231/2012 on Food Additive Specifications

8. EFSA Journal – Safety Assessment of Cellulose E460 (2017)

9. JECFA Monographs on Food Additives – Microcrystalline Cellulose

10. Food Standards Australia New Zealand – Additive Code 460