Within the supplement industry, colloid microcrystalline cellulose high-performance supplements represent a formulation category where MCC is leveraged as a critical functional ingredient, not merely a filler. These supplements are defined by superior dissolution rates, unmatched blend homogeneity, and exceptional physical stability—all key performance metrics enabled by the unique colloidal properties of microcrystalline cellulose. This approach ensures reliable potency and optimal delivery, setting a new standard for efficacy

Microcrystalline cellulose (MCC) comes from purified wood pulp. People use it to add volume and prevent ingredients from sticking together in supplements. Besides supplements, the food industry also uses it because of its versatility and benefits. Especially useful, this helps form the product without changing the effects of the active ingredients.

Colloidal microcrystalline cellulose in high-performance supplements acts mainly as a functional excipient, rather than a performance-boosting ingredient. It enhances the physical properties, stability, and manufacturability of tablets, capsules, and liquid formulations that contain the active compounds.

The advantages of cellulose are extensive and multifaceted. MCC is plant-based and offers a sustainable option instead of synthetic fillers.

This meets the rising demand for eco-friendly products. Its role as an inert filler means it adds volume without affecting the active ingredients. This keeps the health benefits of the supplement.

People consider MCC to be inert, non-toxic, and non-allergenic. The body does not absorb it. This is one reason people see it as a safe and reliable ingredient in high-performance supplements.

Major pharmacopoeias and food regulations list microcrystalline cellulose for oral use. It is mostly non-toxic. It passes through the digestive system without much change. Many countries allow it as an excipient in dietary supplements and functional foods.

Furthermore, MCC contributes significantly to the structural integrity and functionality of supplements. Its fibrous nature improves the shape of tablets and capsules. It also helps with digestion because dietary fiber is important for gut health. This dual benefit of structural support and digestive aid underscores its importance in supplement formulation.

MCC adds bulk and fiber-like benefits without calories. It helps with digestion and is good for low-calorie or weight-loss products.

Formulators pick colloidal MCC because it helps make tablets through direct compression. It also creates stable suspensions and provides a good mouthfeel. Plus, it does this without adding extra calories or changing important nutrient ratios.

In high-performance products, dose precision, quick disintegration, and physical stability are very important. It acts as a reliable “platform” that supports the active ingredients.

The production of microcrystalline cellulose uses acid hydrolysis on wood pulp. This process breaks down cellulose fibers into smaller crystalline structures. The result is a fine, white powder characterized by excellent flow properties, which are crucial for efficient manufacturing processes.

These flow properties make sure that each supplement has an even mix of ingredients. This is important for keeping the dosage and effectiveness consistent.

The acid hydrolysis process not only refines the cellulose but also enhances its performance in various applications. The resulting microcrystalline structure provides a consistent texture and stability to supplements, making it easier to compress into tablets or encapsulate in capsules. This consistency is vital for manufacturers aiming to produce high-quality supplements that meet rigorous industry standards.

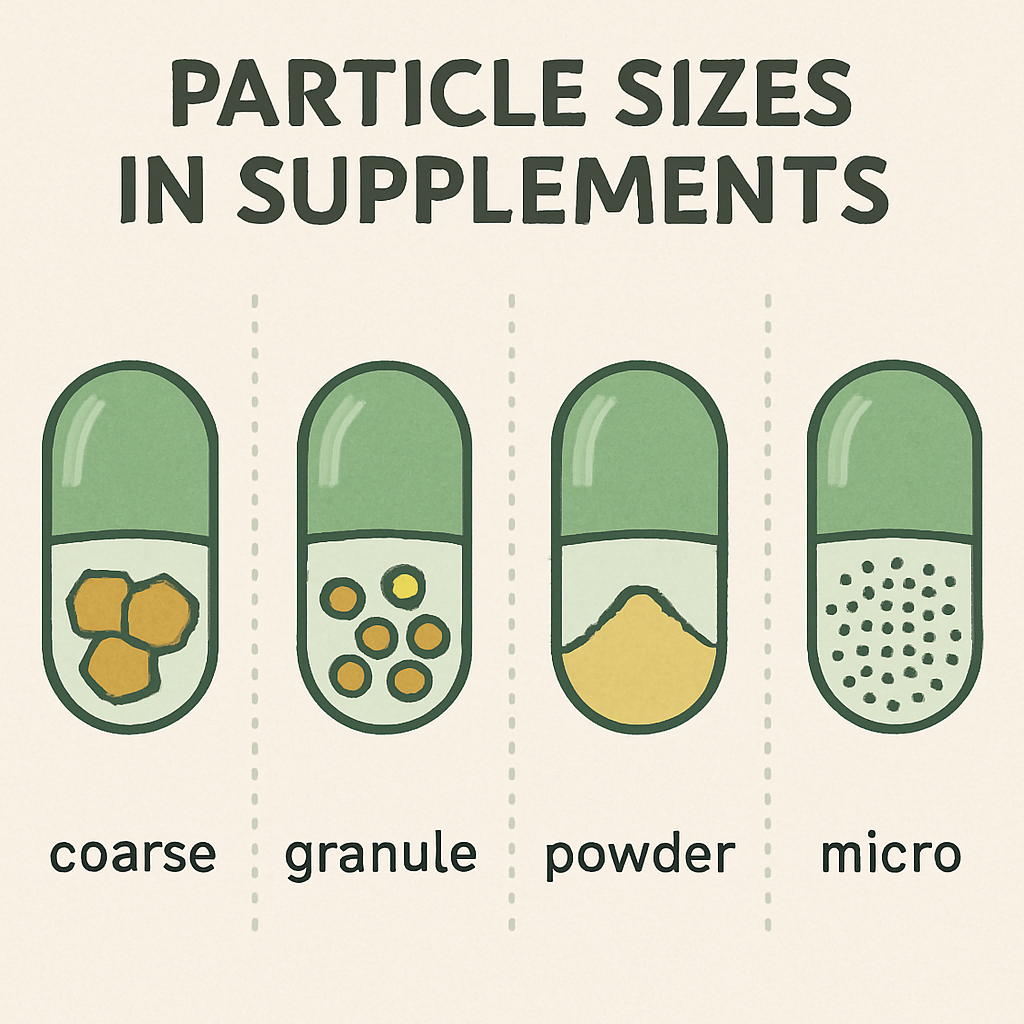

Particle size is a critical factor in the performance of microcrystalline cellulose in supplements. Smaller particles are associated with improved binding properties, which are essential for the formation of tablets. By choosing the right particle size, manufacturers can make supplements that work well and are easy to use. This gives consumers a better experience.

Because MCC performance varies by grade, particle size, and compressibility, selecting high-quality MCC is essential for achieving consistent outcomes in advanced supplement formulations.

One of the defining features of microcrystalline cellulose is its exceptional flow properties. This characteristic is particularly advantageous in supplement manufacturing, as it facilitates smooth processing and minimizes the risk of clumping or uneven ingredient distribution. MCC helps improve flowability. This ensures that manufacturers make tablets accurately, which reduces waste and boosts production efficiency.

The superior flow properties of MCC also contribute to the scalability of supplement production. Manufacturers want to meet growing consumer demand.

They need to produce supplements in larger amounts while keeping quality high. MCC helps improve flow and consistency. This makes the manufacturing process smoother and supports growth and innovation in the industry.

Colloidal microcrystalline cellulose is a specialized form of MCC that exists in a gel-like state when dispersed. This variation significantly enhances the stability and performance of supplements, particularly those requiring precise ingredient distribution. Its unique properties make colloidal MCC an indispensable component in advanced supplement formulations.

Colloidal MCC is a mix of MCC and sodium carboxymethylcellulose (CMC-Na). This blend helps it mix well in water. It also creates a gel network that improves its suspension.

This structure lets it work as a suspending agent, stabilizer, and thickener in water-based systems. This is especially useful in liquid supplement formulations.

Colloidal MCC’s excellent gelling, stabilizing, and thickening properties also improve the palatability and swallowability of oral supplements, enhancing patient compliance.

In the realm of dietary supplements, colloidal MCC functions as a stabilizer and emulsifier. Its distinctive structure enables it to maintain the suspension of active ingredients, thereby ensuring consistent delivery and efficacy. This is especially beneficial in liquid or semi-solid formulations, where ingredient separation can compromise the product’s effectiveness and consumer satisfaction.

Its enhanced suspending, thickening, and stabilizing capabilities make it ideal for high-performance liquid systems where uniformity and stability are critical.

Moreover, colloidal MCC’s ability to act as an emulsifier enhances the bioavailability of certain nutrients, facilitating better absorption in the body. This ability is important for supplements with fat-soluble ingredients. It helps the body use the nutrients effectively. By improving nutrient absorption, colloidal MCC plays a key role in maximizing the health benefits of supplements.

Its chemical inertness also ensures compatibility with a wide range of nutrients and active ingredients without risking degradation or interaction.

In sports and “high performance” supplements, colloidal MCC helps deliver ingredients like amino acids, creatine, or stimulants. It provides a stable and easy-to-use dosage form.

Its main functions are to improve tablet hardness and compressibility. It helps with disintegration and prevents sedimentation in liquids. It also provides consistent dosing by acting as a filler and binder.

Leading global manufacturers of colloidal MCC include Roquette, JRS, Remin, Mingtai, and ACTA. ACTA in mainland China offers the best value for money. Its products match the quality of European and American brands. Retailers sell them in over 80 countries around the world.

The ACTA brand is made by Qingdao ACTA Biotechnology Co., Ltd. This company has quickly increased its production of colloidal MCC.

The company makes 3,000 tons each year. It has more than 200 engineers. This helps ensure good quality and strong technical skills.

Microcrystalline cellulose is well-known for working well with many organic solvents. This quality is important for creating different supplement formulations. This compatibility allows manufacturers to create products tailored to specific consumer needs, offering flexibility in formulation and application.

Adding MCC to supplements can greatly improve their shelf life. This is important for product quality and customer satisfaction.

Its moisture-absorbing properties help to prevent spoilage and maintain the integrity of active ingredients over time. This helps the supplements stay effective for a longer time. It also supports making high-quality products that consumers can trust.

MCC preserves vitamins and probiotics, keeping supplements effective and reliable.

However, too much MCC can cause mild stomach discomfort in sensitive people. This is important to consider when designing formulations.

Beyond supplements, microcrystalline cellulose has a multitude of applications in the broader food industry. MCC adds bulk and stability, making it useful in supplements and everyday foods

As a plant-based ingredient, microcrystalline cellulose aligns with the increasing consumer demand for sustainable and environmentally friendly products. Its renewable nature and minimal environmental impact make it an attractive choice for both manufacturers and consumers. Using MCC helps companies make healthier, more sustainable products. It improves texture and stability, replaces synthetic additives, lowers calories, and appeals to eco-conscious consumers

In high-performance supplements, colloidal microcrystalline cellulose is an important ingredient. It helps them mix evenly, stay stable, and maintain quality.

In complex supplements, colloidal MCC helps keep ingredients even, stable, and effective, ensuring the product works consistently.

As people look for healthier supplements, it’s useful to know how microcrystalline cellulose (MCC) is used. MCC helps makers create products that work well and satisfy consumers

If you make supplements, you might want to improve your formulas. If you use supplements, you may want to know what is in them. Microcrystalline cellulose is an important ingredient to understand.

The supplement industry is always changing and improving. Using colloid microcrystalline cellulose will be important.

This will help create products that support health and well-being for people around the world. By using its strengths, the industry can keep leading in offering high-quality, sustainable, and effective health solutions. These solutions meet the diverse needs of today’s health-conscious consumers.